Best Metal Door Frame Roll Forming Machines: High-Quality Metal Door Frames Made Easy

Introdução às máquinas de formação de rolos de portas metálicas

Metal door frame roll forming machines are vital tools in the building and factory sectors. These devices are built to create steady, top-notch steel door frames quickly while cutting down on wasted materials. They’re widely used in construction for making things like metal roofing, wall panels, drywall frames, partition walls, purlins, ceiling panels, roller shutter doors, and door frames. Their accuracy and automatic features make them perfect for crafting all sorts of designs, from basic home door frames to tough, industrial-strength setups.

How Metal Door Frame Roll Forming Machines Work: A Step-by-Step Guide

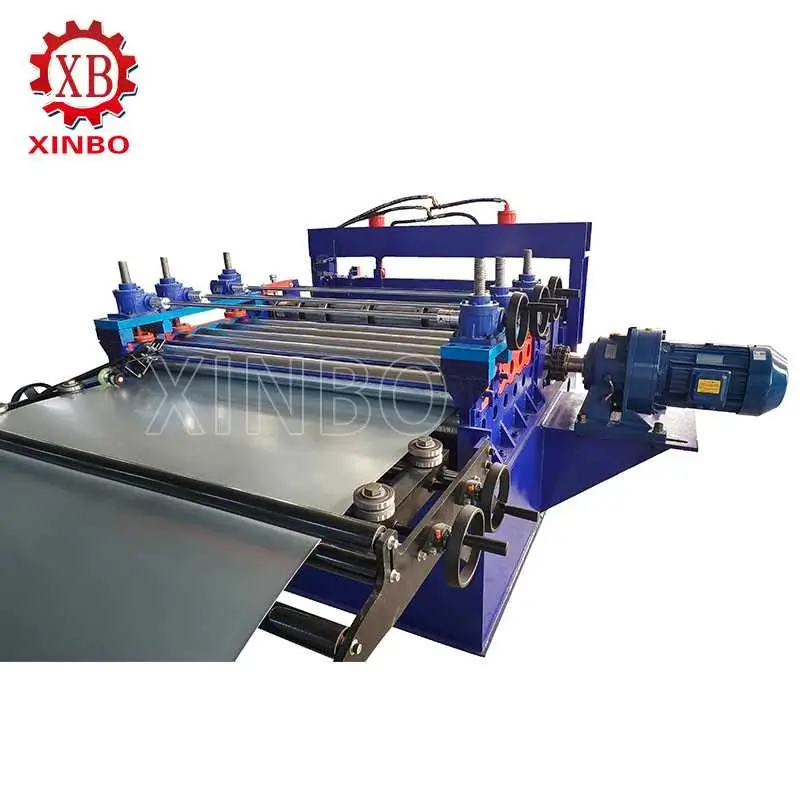

Running a metal door frame roll forming machine involves a few connected steps:

- Manual Decoiling: It all begins by placing a coil of sheet metal onto a manual decoiler.

- Plataforma de Alimentação: Then, the metal strip is led into the machine using a guiding platform.

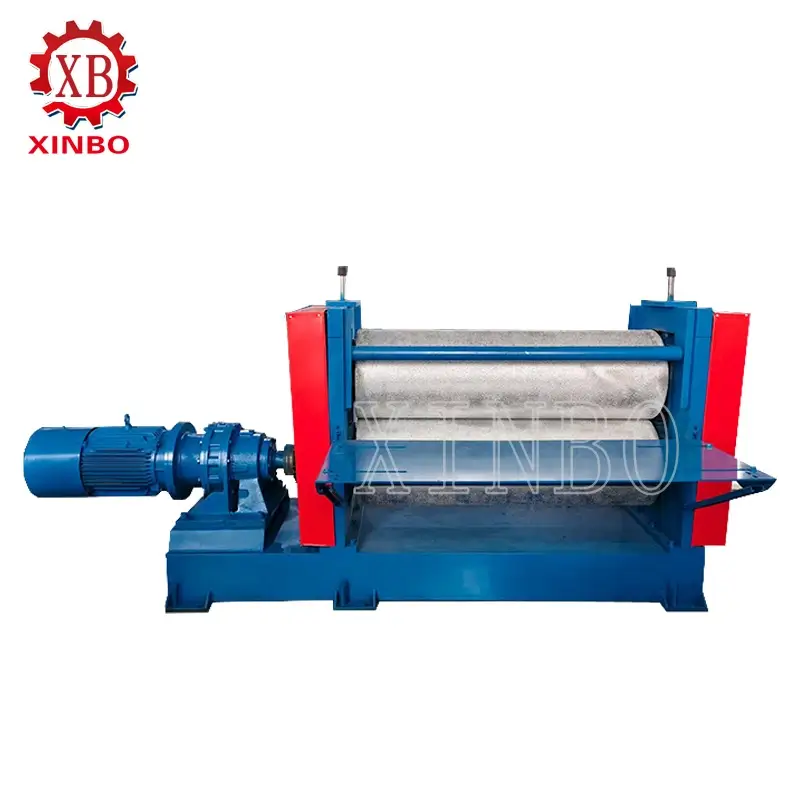

- Main Roll Forming Machine: Next, a set of rollers slowly turns the flat strip into the needed shape.

- Automatic Cutting System: After shaping, the piece is sliced to the right length with hydraulic or mechanical cutters.

- Estação hidráulica: This part gives power to the punching and cutting actions.

- Computer Control Box: It runs everything using PLC systems to keep things precise and repeatable.

- Finished Panel Receiving Table: Finally, this collects the ready pieces for packing or further steps.

Fluxo de trabalho:

Manual decoiler—-Feeding Platform—-Main Roll Forming Machine—-Automatic Cutting System—Hydraulic Station—Computer Control Box—-Finished Panel Receiving Table

This smooth process allows fast output with very little need for hands-on work.

Key Benefits of Using Metal Door Frame Roll Forming Machines

Metal door frame roll forming machines bring some great perks:

- Alta eficiência: They keep working without much stopping, saving time.

- poupanças de materiais: Smart planning cuts down on leftover scraps.

- Engenharia de Precisião: This makes sure every piece matches in size and quality.

- Reduced Labor Costs: Since it’s mostly automatic, you don’t need as many workers.

- Capacidades de personalização: They can easily switch to make different shapes and sizes.

These machines craft steady shapes, sizes, and thicknesses in metal sheets. As a result, the end product always looks and works the same.

Such advantages make these tools a must-have for companies wanting to grow their operations.

Types and Specifications of Metal Door Frame Roll Forming Machines

You can find different kinds of metal door frame roll forming machines for various jobs:

- Standard Steel Door Frame Machines: Great for regular home or business needs.

- Heavy-Duty Industrial Machines: Built for thicker stuff and stronger builds.

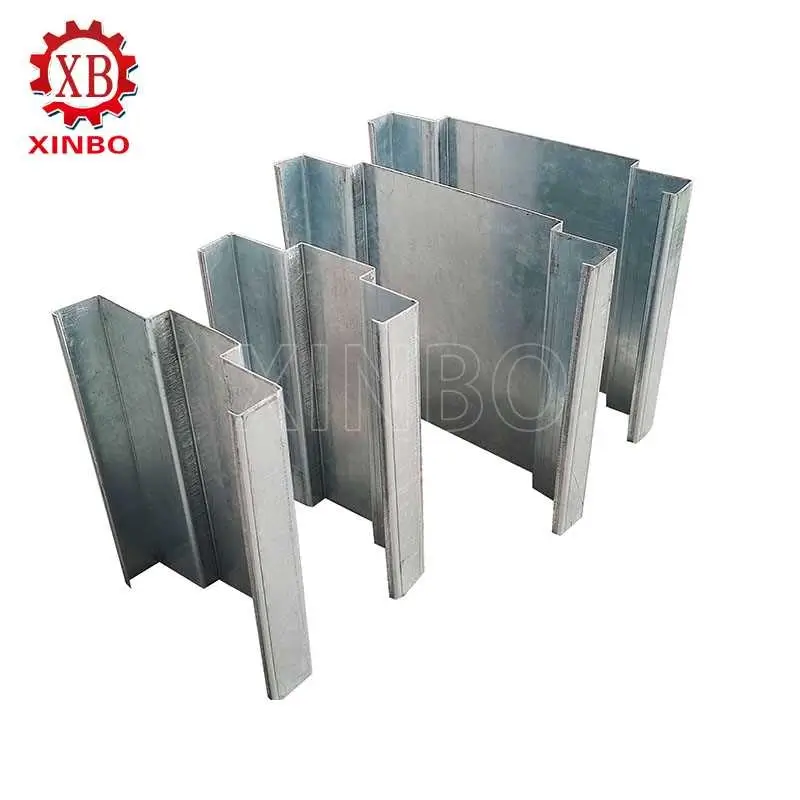

- Channel-Type Machines: Made just for creating U-shaped or channel designs.

Important details include:

- Material thickness range: 0.8mm–2.5mm

- Coil width capacity: 100mm–400mm

- Production speed: 8–25 meters per minute

- Power requirements vary based on model complexity

We build and offer various machines to fit every customer’s wishes.

Knowing these details helps buyers pick the right machine for their work goals.

Opções de personalização

Being able to tweak things is a big deal with top makers like XinBo. Our skilled design team shapes the machine fully based on what the customer wants. Choices include:

- Profile shape variations (U-channel, L-frame)

- Embossed surface finishes

- Integrated punching patterns for locks or hinges

- Adjustable width settings

- Modular tooling systems for quick changeovers

These options help makers meet all kinds of market needs with ease.

Applications of Metal Door Frames Produced by Roll Forming Machines

Metal door frames are handy in many areas because of their flexibility:

- Edifiços residenciais: Perfect for inside and outside doors since they’re strong and resist rust.

- Commercial Spaces: Used as fire-safe frames in places like offices, malls, and hospitals.

- Facilidades Industriais: Tough frames that hold up in rough spots like factories or storage areas.

Roll forming machines also help in the car industry by making parts like door frames, rolling up doors, and guiding rails.

From houses to secure setups, these frames offer strength and usefulness.

Maintenance and Care for Steel Door Frame Roll Forming Machines

Taking good care of these machines makes them last much longer:

- Daily cleaning of rollers and surfaces

- Regular oiling of moving bits

- Checking hydraulic systems from time to time

- Testing punching tools to keep them accurate

If looked after well, a metal door frame roll forming machine can run smoothly for 10–15 years with few problems.

Regular care keeps the output steady and stops expensive breakdowns.

Choosing the Right Metal Door Frame Roll Forming Machine: Buyer’s Guide

To pick the best machine, follow these tips:

- Think about how much you need to produce.

- Decide on the material, like galvanized steel or aluminum.

- Go for a simple or high-tech model based on how much automation you want.

- Check the supplier’s background, including stuff like CE or ISO certifications.

- Look into after-sales help, such as training or spare parts.

We provide top-quality products and a full package of “product designing, assembling, installation, and after-sales service” for a smooth experience.

Making a smart choice ensures success for years to come.

Future Trends in Metal Door Frame Roll Forming Technology

Some new ideas are coming up in this field:

- AI tools to predict when maintenance is needed

- IoT setups for checking machines from afar

- Using eco-friendly stuff like recycled steel

- Quicker systems to swap tools for better flexibility

We promise high-quality machines and fresh ideas, thanks to our skilled and seasoned engineers.

These updates aim to boost speed while sticking to earth-friendly building rules.

FAQ

Q1: What materials can be used?

A1: Galvanized steel, cold rolled steel, and aluminum up to 2.5mm thick.

Q2: Can I change my machine to fit my needs?

A2: Yes—XinBo provides complete OEM/ODM customization based on what clients want.

Q3: How long until delivery?

A3: Usually 30–60 days, depending on the design; we also optimize shipping containers to cut costs.

We design roll forming machines to fit into one 20feet or 40feet container, which helps save on shipping fees for customers.

Conclusion: Elevate Your Production with the Best Metal Door Frame Roll Forming Machines from XinBo

Metal door frame roll forming machines offer amazing speed, accuracy, and flexibility across many fields. XinBo is a reliable name, providing tailored options supported by expert engineering teams. Botou Xinbo Import & Export Co., Ltd., started in 2015, is a trusted supplier of various metal roof sheet roll forming machines and door frame roll forming machines. We happily accept ODM and OEM requests.

Reach out to us today for the best deals!

Postos relacionados

-

Automatic Metal Embossing Machine Guide: Top China Embossing Machines for Metal Plates

-

How Double Layer Roof Panel Roll Forming Machines Save Time and Costs in Roofing

-

Ibr Roof Sheet Making Machine: A Must-Have for Modern Construction

-

Advantages of Using High-Speed Automatic Steel Coil Slitting Lines | Steel Coil Slitting Line Manufacturer

-

Best Metal Door Frame Roll Forming Machines: High-Quality Metal Door Frames Made Easy

Boa qualidade

A máquina XinBo que faz CO. LTD é um fabricante profissional e exportador em máquina de formação de rolos,

Vê mais→

Espanhol

Espanhol Rússia

Rússia