How to Source a Standing Seam Roof Roll Forming Machine from China Successfully

Sourcing a standing seam roof roll forming machine from China has turned into a popular choice for construction material makers, roofing contractors, and metal fabrication businesses around the world. China has a well-developed roll forming sector, solid engineering skills, and good options for custom work. This makes it a key place for global supply. Still, getting the right machine takes more than just locating a factory. It needs clear technical knowledge, good talks with the supplier, and a careful step-by-step check process.

This guide shows how to source a good machine well. It looks at production basics, performance points, ways to check suppliers, and value over the long run.

Understanding Standing Seam Roof Roll Forming Machine Technology

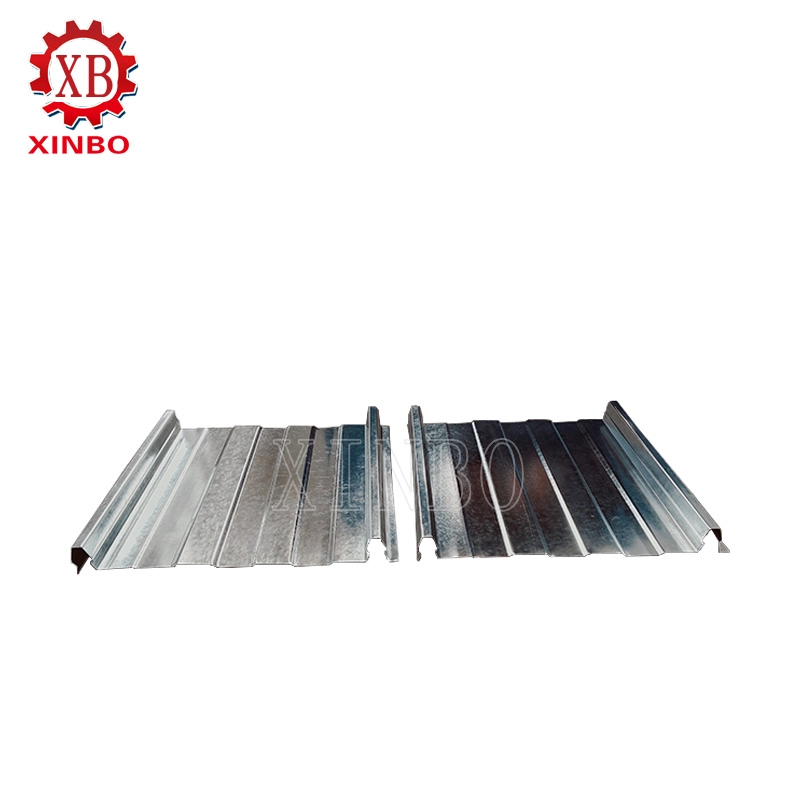

A standing seam roof panel roll forming machine shapes metal coils into precise roofing panels with hidden fasteners. These panels see wide use in industrial buildings, commercial roofs, and nice-looking architectural metal roofing. They offer strong waterproofing and a clean look.

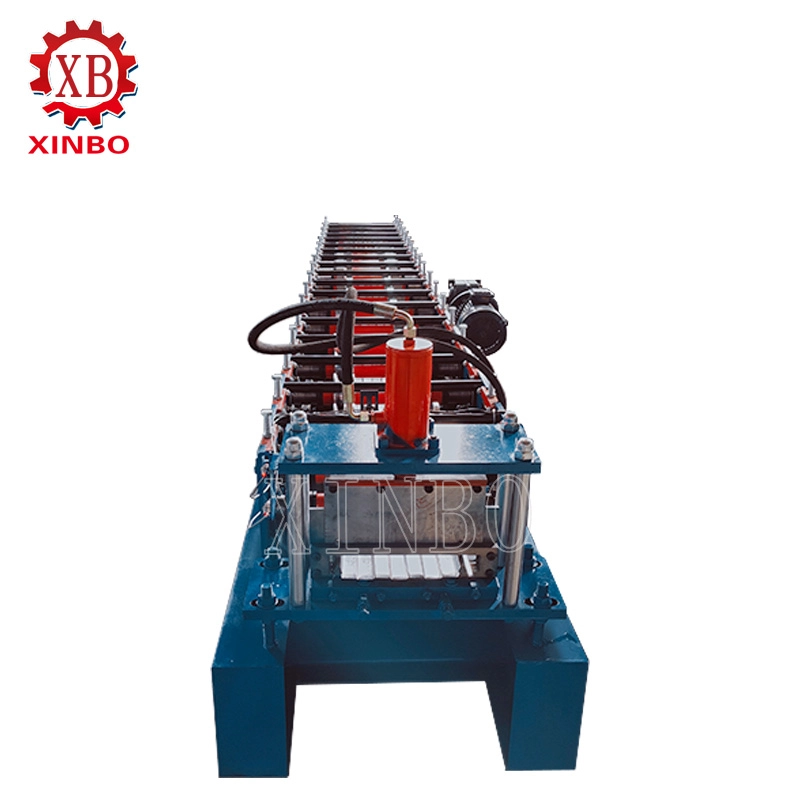

Unlike basic sheet forming gear, a standing seam metal roof sheet roll forming machine has to keep very tight size accuracy. This ensures good seaming at the job site. Because of this, the machine design, number of forming steps, and control setup matter a lot.

Material Compatibility and Forming Stability

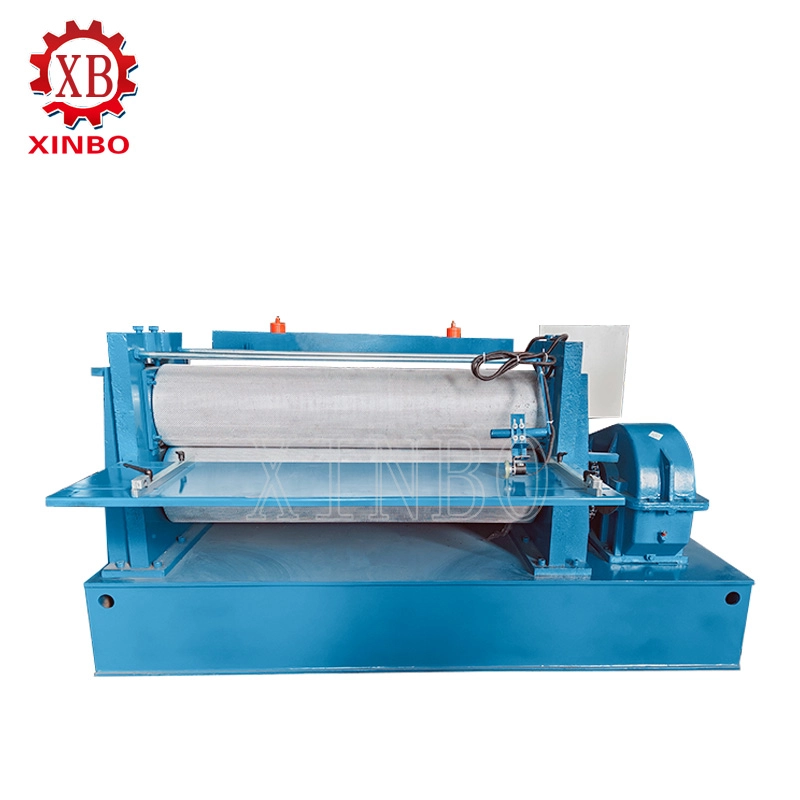

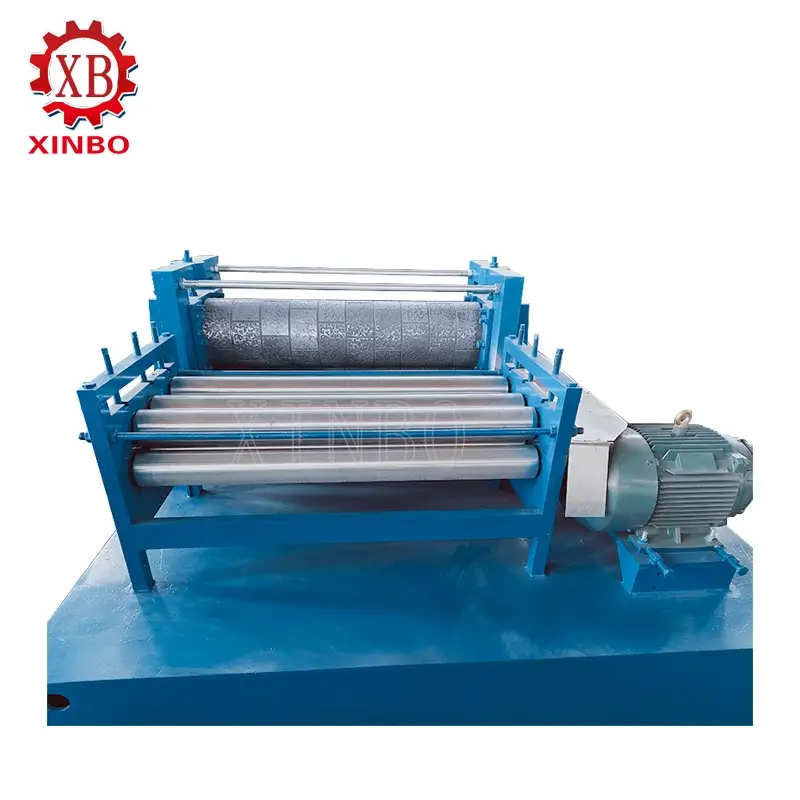

In real use, machines often work with galvanized steel, aluminum, or color-coated steel. A durable standing seam roof sheet roll forming machine gives steady results across various material thicknesses. It avoids too much shaking or marks on the surface. The hardness of the rolls, straightness of the shafts, and strength of the frame all play a big role in steady work over time.

Key Performance Factors in Standing Seam Roof Roll Forming Machine Selection

Precision Control and Automation Level

Newer projects often need the same high quality every time. A highly intelligent standing seam roof roll forming machine uses PLC control, servo tracking, and automatic cutting. This cuts down on hand work. Smart systems lower mistakes from people, boost output speed, and make things easier for buyers overseas who run plants far away.

Older control setups, however, can cause uneven panel lengths. That leads to trouble during on-site seaming.

Output Quality and Surface Protection

A high quality standing seam metal roof sheet roll forming machine protects the surface coating while forming. Good roller polishing, steady forming speed, and smart pass design prevent scratches or cracks in the coating. These things matter for how long the roof lasts.

For big production runs, some companies need a bulk standing seam roof sheet roll forming machine. It must handle long continuous work without getting too hot or losing power.

Evaluating Chinese Manufacturers Beyond the Product Brochure

Manufacturing Capability and Engineering Depth

When you source from a standing seam metal roof sheet roll forming machine manufacturer in China, look past just the sales sheets. Check if the supplier designs the machines themselves, manages tight machining limits, and runs full tests before sending.

Good suppliers usually share engineering drawings, forming simulations, and help with setup.

OEM and ODM Flexibility

Many buyers from other countries want changes to match local roofing rules. An ODM OEM standing seam roof roll forming machine setup lets buyers adjust panel width, rib height, or seaming shape. They do this without starting over on the whole line. This option helps a lot for firms building their own special roofing products.

Supplier Communication and Documentation Standards

Technical Transparency

Good paperwork shows a supplier knows their job. Reliable standing seam roof panel roll forming machine suppliers give clear manuals, wiring diagrams, and care instructions in English. This cuts downtime and makes training operators simpler after the machine arrives.

Quality Control and Testing Process

Before you buy standing seam metal roof sheet roll forming machine solutions from China, ask about their factory test steps. Running trials with the materials you specify checks accuracy and steady performance.

Suppliers who send videos of inspections and do pre-shipment checks show they trust their work.

Logistics, Installation, and After-Sales Considerations

Export Packaging and Shipping Readiness

A china standing seam metal roof sheet roll forming machine needs good prep for long trips. Strong anti-rust steps, tough packing, and a design that comes apart in modules lower risks during setup at your site.

Long-Term Technical Support

Even solid machines need help during startup and later updates. A good supplier keeps spare parts ready, offers remote fixes, and makes sure upgrades work well. This matters most for control system changes down the road.

Managing Risk and Ensuring Long-Term Value

Good sourcing means more than just getting equipment. It means getting a dependable production tool. A well-chosen standing seam roof roll forming machine helps keep product quality steady, cuts repair costs, and strengthens your place in the market.

By paying attention to engineering skills, smart controls, and clear communication, buyers lower risks in daily work. They also get the best return on their money.

Frequently Asked Questions (FAQ)

Q1: What materials can a standing seam roof roll forming machine process?

Most machines handle galvanized steel, aluminum, and pre-painted steel. Thickness ranges get set during the design stage.

Q2: Is automation necessary for overseas buyers?

For work in other countries, smart control systems make running easier. They cut training time and help keep results the same.

Q3: How long does installation usually take?

With good prep and remote help, setup and testing often finish in just a few days.

Q4: Can machines be customized for local roofing standards?

Yes. ODM and OEM setups allow changes to profiles and structure to fit local needs.

Work with a Professional Standing Seam Roll Forming Machine Manufacturer

Partner with XINBO for Reliable Roll Forming Solutions

Xinbo is a professional Chinese manufacturer specializing in roll forming machinery for metal roofing and structural applications. With in-house engineering, advanced machining equipment, and extensive export experience, XINBO supports global clients with OEM and ODM manufacturing, technical documentation, and long-term service support.

Whether you are expanding production capacity or developing a customized roofing system, XINBO provides stable manufacturing capability, rigorous quality control, and responsive technical assistance to support your project from concept to operation.Contact XINBO at serena@cnxinbo.net.

Postos relacionados

-

China Sheet Metal Embossing Machine Company: What to Look for Before Buying

-

Considerations for Choosing the Right Metal Wall Panel Roll Forming Machine

-

XINBO: Leading Automatic Sheet Metal Embossing Machine Supplier in China

-

How a Metal Signboard Cladding Panel Roll Former Transforms Modern Storefront Design

-

Applications of Light Steel Metal Keel Roll Forming Machines Across the Building Industry

Boa qualidade

A máquina XinBo que faz CO. LTD é um fabricante profissional e exportador em máquina de formação de rolos,

Vê mais→

Espanhol

Espanhol Rússia

Rússia