Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

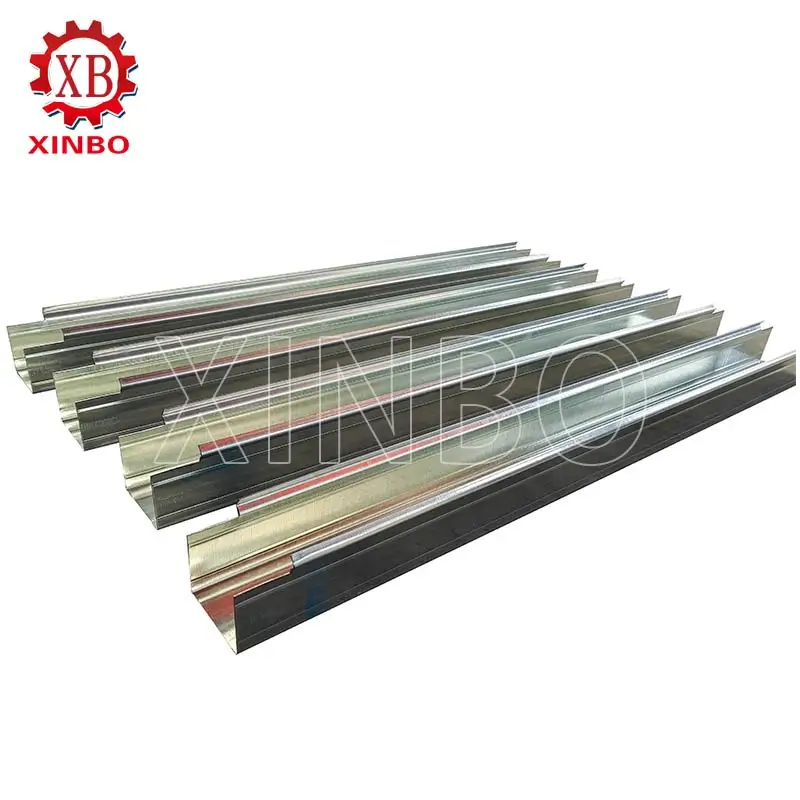

VIEW MORE→A poultry feeding trough roll forming machine is a unique tool for industry. It makes feeding troughs, which are key parts in poultry farming. This machine shapes metal sheets, usually galvanized steel, into standard troughs. It uses steps like unwinding, flattening, hole-punching, rolling, and cutting.

These troughs are used in automatic feeding systems for birds like chickens, turkeys, guinea fowl, and ducks. The rolling technology in this machine ensures exact shaping and cutting. It meets specific sizes and needs.

The machine is very efficient. It is great for large poultry farms with automatic feeding systems. By making uniform and strong troughs, it helps these systems run smoothly. The raw materials are usually galvanized steel coils. These have a strength of ≤235 MPa and a thickness of about 2 mm. This makes the troughs tough and resistant to farm conditions.

The poultry feeding trough roll forming machine has many modern features. These make it a vital tool for making poultry equipment:

The machine mainly uses galvanized steel coils. These can weigh up to 5 tons. The outer diameter can reach φ1600 mm. The inner diameter ranges from φ480 to φ508 mm. This material choice ensures resistance to rust and long-lasting use.

The machine has a top speed of 20 m/min. When punching, it runs at 15 m/min. This allows it to meet high-volume production needs quickly.

Hydraulic Uncoiler: It has a 3-ton capacity and a 400 mm cantilever width.

Leveling Device: It uses seven rollers to keep sheets flat.

Punching Station: It has two stations with H-shape and notch molds. A 2.2 KW servo motor powers it.

Roll Forming Section: It includes 19 roller stations made from Cr12 material. The material has a hardness of HRC58–62°. The roller shaft is φ55 mm in diameter.

Control System: It uses a PLC-based automatic control with a touchscreen. This makes it easy to operate.

The machine is made from high-quality materials. These include GCr15 rollers and 40Cr shafts. It ensures steady work even with constant use. It is built for 24-hour operation in suitable settings.

The machine has advanced features but takes up little space. Its size is about 25,000 mm long, 2,000 mm wide, and 2,000 mm high. This makes it ideal for factories with limited space.

The poultry feeding trough roll forming machine is mainly used to make high-quality feeding troughs. These are tailored for various poultry farming systems:

The machine creates standard feeding troughs. These are widely used in large poultry farms. The troughs can be customized in width, like 165 mm or 181 mm, based on farm needs.

It supports different bird types. These include chickens, layers, turkeys, guinea fowl, roosters, and ducks. It makes feeding equipment that fits their unique needs.

The machine works well with automatic feeding systems. These systems use motors and feed sensors. The machine ensures accurate feed distribution for all poultry growth stages.

Big farms benefit greatly from this equipment. It produces high-output standard feeding modules. These boost overall farm productivity.

Using this machine offers many benefits. These help explain its wide use in poultry farming:

The machine reaches speeds of up to 20 m/min. This ensures fast production for large operations.

The rolling process ensures every trough has the same shape and size. High-accuracy punching and cutting improve quality. They achieve tight tolerances, like ±1.5 mm in length.

Compared to other methods like stamping or extrusion, rolling uses materials wisely. This reduces waste and lowers production costs.

Galvanized steel resists rust. This ensures troughs can handle tough farm conditions.

Operators can adjust settings easily. They use the touchscreen to make troughs with different specifications. This meets market or farm needs.

PLC control systems reduce manual work. They automate key steps like hydraulic punching. This cuts labor costs and boosts efficiency.

The machine uses strong materials like Cr12 rollers. It provides long-term steady performance. The troughs are also tough. They can handle physical stress in farms.

Automatic feeding systems with this equipment ensure even feed distribution. This reduces stress among birds due to uneven food supply.

By combining modern features with fast production, the poultry feeding trough roll forming machine boosts productivity. It also ensures cost savings in modern poultry farming.

The poultry feeding trough roll forming machine has changed the poultry farming industry. It enables efficient production of high-quality feeding troughs. These troughs are key parts in automatic feeding systems. Such systems are now standard in modern poultry farms.

The machine uses galvanized steel as its main material. This makes troughs resistant to rust. They are strong enough to handle tough conditions in large farms. This strength reduces the need for frequent replacements. It lowers operating costs for farmers.

The rolling technology ensures exact shaping and cutting. This results in uniform products. These improve the efficiency of automatic feeding systems.

Large farms benefit greatly from this technology. The machine’s high speed of up to 20 m/min meets the needs of big farming operations. Its ability to make custom troughs enhances its value. It supports various farming models and bird types like chickens, turkeys, guinea fowl, and ducks.

When picking a poultry feeding trough roll forming machine, Xinbo is a trusted choice. Established in 2014, Xinbo specializes in making high-quality roll forming machines. These are tailored to customer needs.

Xinbo offers custom design services. Their team of skilled engineers and designers can create detailed plans quickly. These meet specific customer needs. Choosing Xinbo means getting a machine that combines innovation, reliability, and affordability. Their focus on customer satisfaction makes them a top pick for poultry farmers worldwide.

What materials can be used with the poultry feeding trough roll forming machine?

The machine mainly processes galvanized steel coils. These have a strength of ≤235 MPa and a thickness of about 2 mm.

How fast can the machine produce feeding troughs?

The top speed is 20 m/min. When punching, it runs at 15 m/min. This suits high-volume production needs.

Can the machine produce customized feeding troughs?

Yes, operators can adjust settings using the touchscreen. This creates troughs with specific sizes and shapes based on customer needs.

What are the key components of this machine?

Main parts include a hydraulic uncoiler, leveling device, punching station, and roll forming section with 19 roller stations made from Cr12 material. The material has a hardness of HRC58–62°. Other parts include a hydraulic oil pump station, output table, and PLC-based control system.

Is maintenance required frequently?

No, the machine is designed for easy upkeep. Durable materials like GCr15 rollers ensure a long service life.

Why should I choose Xinbo over other manufacturers?

Xinbo offers custom designs, competitive prices, and short delivery times. They manage all production steps internally. They also perform strict quality checks for reliable performance.

How does this machine promote sustainability?

The machine uses materials efficiently during production. It supports automatic feeding systems that reduce feed waste. This aligns with sustainable farming goals.

For more details or inquiries about Xinbo’s poultry feeding trough roll forming machines, contact their team now.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→