Good quality

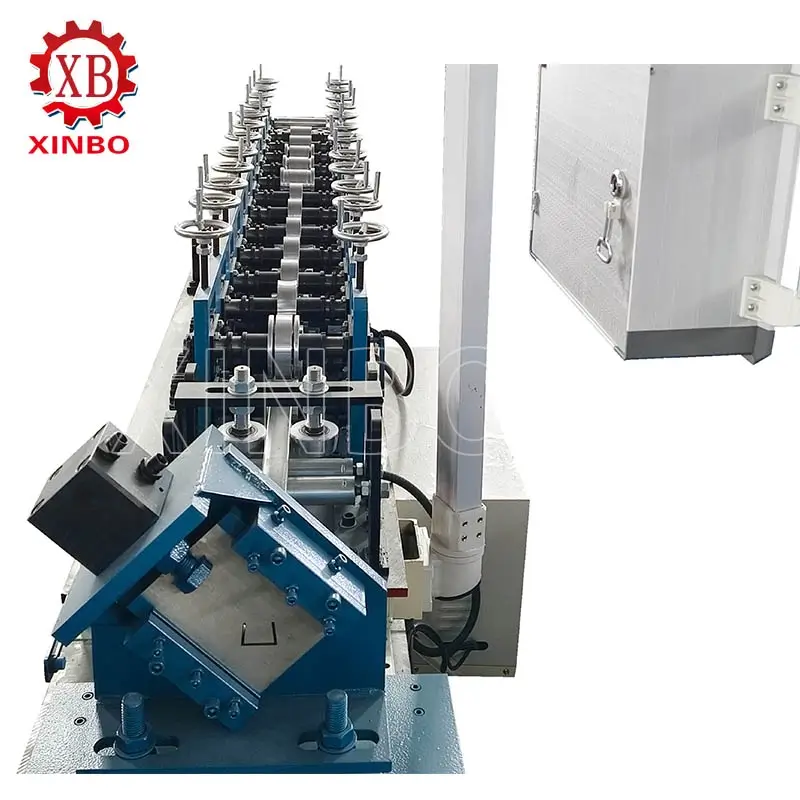

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

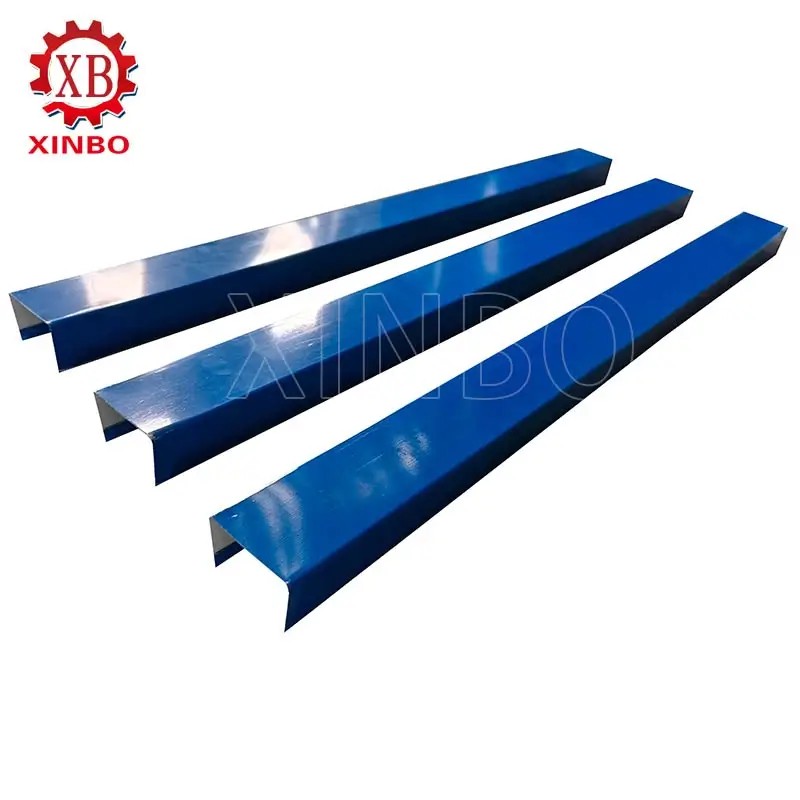

VIEW MORE→In today’s construction world, speed, accuracy, and flexibility are super important. A key part in drywall framing and partition systems is the U Track. It’s a U-shaped metal channel that gives horizontal support for vertical studs. Making these parts fast and right is crucial for big construction jobs. A U Track Roll Forming Machine offers an easy way to make these vital profiles. Roll forming machines are used a lot in many industries to create top-notch, budget-friendly metal products.

A U Track Roll Forming Machine is a special tool for making U-shaped metal tracks from flat steel coils. These tracks are mostly used as top and bottom runners in wall framing, especially in light gauge steel buildings. This machine builds U-shaped tracks that act as the horizontal base for stud partitions, working with vertical C Studs. It can be set up to make different sizes and thicknesses of U Tracks based on project needs.

There are two main types of machines:

These machines are key in modern construction. They make accurate and strong parts every time.

The main idea of a U Track Roll Forming Machine is its steady bending process. Unlike stamping or pressing, roll forming shapes metal slowly through many roller stations without heat. It starts with a flat steel strip, often galvanized to resist rust. The strip is fed from a decoiler into the machine. Each roller station bends the metal a bit more until it forms the final U-shaped profile.

Key parts include:

This method ensures accuracy and speed, perfect for making lots of tracks.

A typical U Track Roll Forming Machine has several systems that work together smoothly:

These parts make production smooth, from raw steel to finished U Tracks, with little human effort.

U Tracks made by roll forming machines are used in many ways across different fields:

Their flexibility makes them essential for both permanent and temporary structures.

Using a U Track Roll Forming Machine brings lots of perks:

These benefits make them a smart choice for manufacturers aiming for high output with few errors.

The production process with a U Track Roll Forming Machine follows a clear path:

This clear process ensures high output with little downtime or mistakes.

As technology grows, new trends are coming for roll forming machines:

These updates will boost productivity and support green goals worldwide.

XinBo is a top manufacturer offering custom roll forming machines solutions since 2014. XinBo machine is a manufacturer which established in China since 2014. The company focuses on building machines to meet customer needs while following global standards like CE certification.

Our factory has skilled engineers and designers. They can create detailed drawings fast to match customer needs. We also have our own workshop with CNC machining and workers. This saves costs and keeps the process on track.

All XinBo machines are checked three times before shipping. We design and machine parts ourselves. This ensures fast delivery of machines that fit your needs. With exports to Europe, Canada, South America, Africa, and the Middle East, XinBo is a great partner for custom roll forming solutions that meet global standards. We work hard to meet all customer needs.

Most often, galvanized steel coils are used. They’re strong and resist rust, perfect for structural jobs.

Yes. Our expert design team will build the machine to fit your exact needs.

Thanks to our CNC machining setup, we design and build machines ourselves. This ensures fast delivery.

Yes. Modern control systems have touchscreen panels. They make operation easy, even for less-skilled workers.

Yes. We offer guaranteed quality products and full service, including design, assembly, installation, and after-sales support.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→