How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

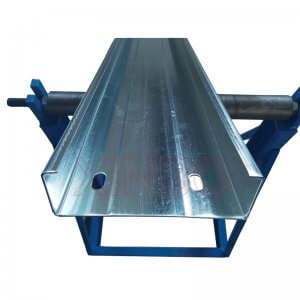

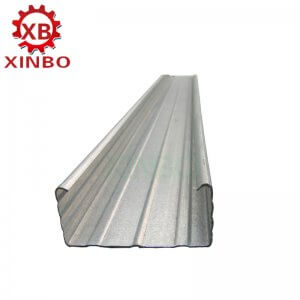

C purlin automatic steel Roll Forming Machine

CZ purlin series is a hot-selling product of industrial roll forming machines, which provides a large number of frames for warehouses and other building manufacturing, and promotes the formation of a large-scale, multi-series, and multi-category equipment supply system.

In recent years, Xinbo has been engaged in software and industrial control. The technology in this field is also gradually embedded in the engineering construction product series, achieving typhoon-level breakthroughs such as high-precision and high-speed servo control industrial computer operation, remote data interactive online programming, etc.

|

No. |

Item |

Specification |

|

1. |

Processing Material |

PPGI,GI,AL |

|

2. |

Formed Width(mm) |

As drawing |

|

3. |

Processing Thickness(mm) |

1-1.5 |

|

4. |

Material of Rollers |

45# steel,with hard chrome coated |

|

5. |

Diameter of Shaft |

Ф80mm |

|

6. |

Production Speed |

0—15m/min |

|

7. |

Roller Driven |

Decelerating Motor+Chain Transmission |

|

8. |

Cutting Model |

Hydraulic Profile Cutting |

|

9. |

Length Measurement |

Encoder |

|

10. |

Control Style |

PLC control |

|

11. |

Total Power |

5.5KW |

|

12. |

Voltage |

380V 50HZ or at buyer’s request |