Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

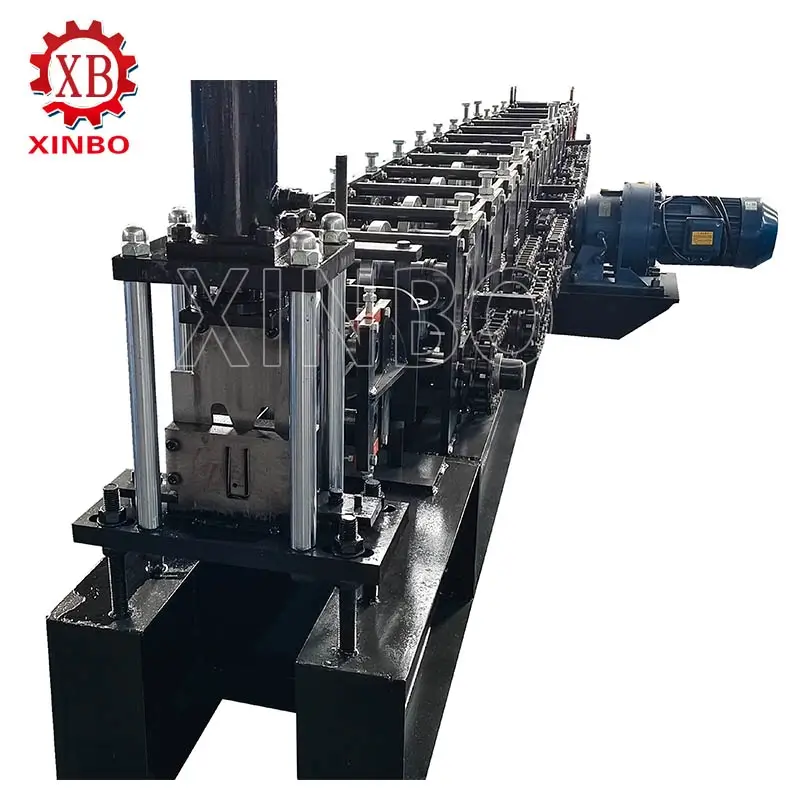

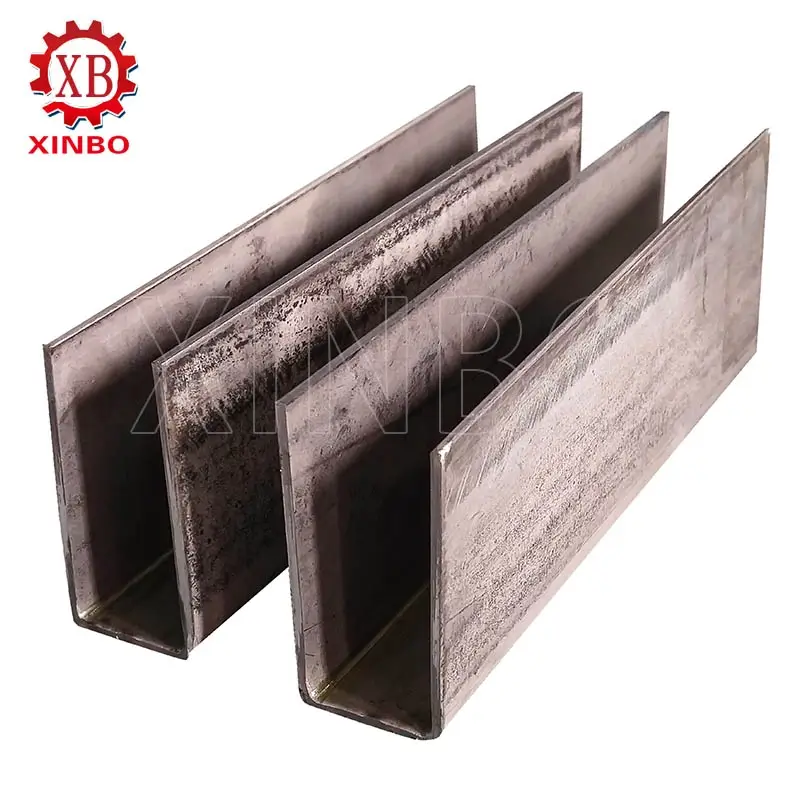

VIEW MORE→A U channel roll forming machine is a special tool. It makes U-shaped metal channels. These are key parts for many building projects. The machine uses roll forming tech. It takes flat metal strips and shapes them. The strips are often galvanized steel, cold-rolled steel, aluminum, or stainless steel. They pass through rollers to form exact U-shaped profiles. The process runs smoothly. It wastes little material. It gives steady results.

The process starts by uncoiling a metal strip. The strip goes through roller stations. These shape it into a U profile. Then, it’s cut to the right length. Hydraulic or flying shear systems do the cutting. These machines use programmable logic controllers (PLCs). This gives better control and accuracy.

U channel roll forming machines have different specs. These depend on the maker and use. Common features include:

Rollers are heat-treated and chrome-plated. This fights wear and ensures long use. Extra features like punching systems or embossing add flexibility.

U channel roll forming machines can be tailored a lot. Makers can design them for unique U channel sizes. They can add punching, embossing, or logo stamping. This makes them work for many projects.

Toughness is a big factor. Heat-treated rollers and strong build materials make them last. They perform well for a long time.

U channel roll forming machines are vital in garage door making. They create strong parts. These U channels ensure smooth operation and toughness for different garage door types:

These U channels boost garage door strength and function. They are key in making high-quality doors.

The market for U channel roll forming machines is strong. Many global makers meet different needs. Companies like XinBo Machine are trusted suppliers. They offer new designs tailored to customers. XinBo makes roll forming tools that meet global standards. These include UL, TUV, CE, CQC, ROHS, and REACH certifications.

XinBo has over 10 years of experience. They ensure quality with strict checks at every production step. They customize machines and keep prices fair. This makes them a top choice worldwide.

Good care is key to keep U channel roll forming machines running well. Best practices include:

Following these steps cuts downtime. It lowers repair costs. It ensures steady quality over time.

U channel roll forming machines are very efficient. They make key parts for garage doors. They offer custom options for many industry needs. With regular care and advanced tech from makers like XinBo, businesses get great performance. Their equipment stays reliable for years.

When running a garage door U channel roll forming machine, several things matter. They ensure top performance and safety. Customization is key. Customers should give profile drawings or samples to suppliers. This ensures the machine makes U channels that fit specific needs.

Production line choices are important too. Continuous lines are very efficient. They suit large-scale production. Discontinuous lines work better for smaller spaces or lower demands.

Safety and training are crucial. Operators need proper training. They must handle the machine well and follow safety rules. This boosts work output. It also cuts accident risks. Regular care like cleaning, lubricating, and checking for wear helps the machine last. It keeps output quality steady.

The demand for garage door U channel roll forming machines follows industry trends. Sectional overhead garage doors are very popular. They increase the need for high-quality roll forming machines. These doors save space and are tough. They’re a top pick for homes and businesses.

Makers focus on automation and faster production. Advanced features like PLC control systems allow exact operation. They also support customization. Multi-profile abilities are growing too. They let makers produce different U channel sizes and designs with one machine.

XinBo is a dependable supplier. They make garage door U channel roll forming machines. With over 10 years of experience, XinBo creates machines that meet global standards. These include UL, TUV, CE, CQC, ROHS, and REACH certifications.

XinBo’s factory has skilled engineers and designers. They make detailed drawings based on customer needs quickly. This ensures products match client specs exactly. The company has its own workshop. It uses CNC machining. This cuts costs while keeping quality high across production.

Each machine is checked three times before shipping. This ensures steady high quality. XinBo customizes machines and offers fair prices. This makes them a great choice for businesses wanting reliable roll forming tools. Contact XinBo for your machine needs today!

These machines work with galvanized steel, cold-rolled steel, aluminum, and stainless steel. These materials are strong and tough for building projects.

Regular care is key. Clean daily to remove debris. Lubricate gears and bearings often. Check oil levels regularly. Inspect rollers for wear or rust. Tighten bolts now and then. Keep coolant mixes right. Clean air filters often. Check hydraulic hoses for leaks monthly.

These machines are mainly used in the garage door industry. They make parts for sectional overhead doors and rolling shutter doors. They also produce tracks for sliding doors and elevator shafts.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→