Automatic Metal Embossing Machine Guide: Top China Embossing Machines for Metal Plates

In factories that make stuff, getting things just right and tough is super important. Whether you’re making building panels, car parts, or cool signs, an automatic metal embossing machine turns flat metal sheets into neat designs. These machines press patterns, logos, or useful textures onto metal with steady force. They make things look good and work better. If you’re looking for trusty embossing machines for metal or China embossing machines for metal plates, this guide has all you need.

China leads in metal shaping tools. They make affordable, high-quality machines. With over ten years of new ideas, companies like XINBO set the bar for custom machines that fit global needs.

What is an Automatic Metal Embossing Machine?

An automatic metal embossing machine is a special tool for factories. It makes raised or sunken designs on metal sheets or plates. Unlike hand tools, these machines use hydraulic, air, or mechanical presses with precise rollers. They handle big batches fast.

Here’s how it works. A metal sheet—like stainless steel, aluminum, or galvanized steel—goes between two carved rollers. The top roller pushes down hard. This shapes the metal to match the design. Machines use PLC (Programmable Logic Controllers) systems to control speed, pressure, and alignment. This gives steady results. They can work with metal from 0.5mm to 3mm thick and up to 1.5 meters wide. They’re great for things like fancy floors or non-slip safety plates.

For China embossing machines for metal plates, they often include roll-forming. These machines don’t just emboss. They can unwind, flatten, and rewind sheets in one go. This saves work and waste. They follow IEC rules for safety and performance, making them good for export to Europe, the UK, and North America.

Why pick automatic over manual? They’re way faster—making 10-20 meters per minute. They’re also super accurate, cutting down mistakes like uneven designs or warped metal. In big industries like building or cars, where plates need to resist rust or heavy use, embossing adds grip, branding, or strength without hurting the metal.

How Does an Automatic Metal Embossing Machine Work?

Knowing how an embossing machine for metal works makes it less mysterious. The process has four main steps:

-

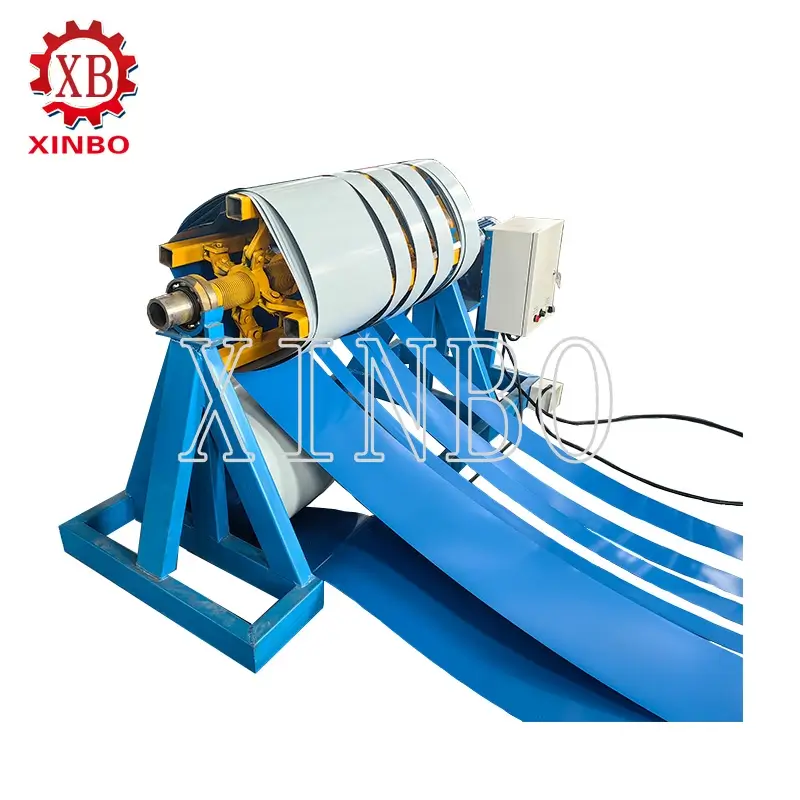

Loading and Prep: A hydraulic uncoiler loads metal coils (up to 10 tons) into the machine. Rollers flatten the sheet to avoid bends. This ensures it goes in straight for embossing.

-

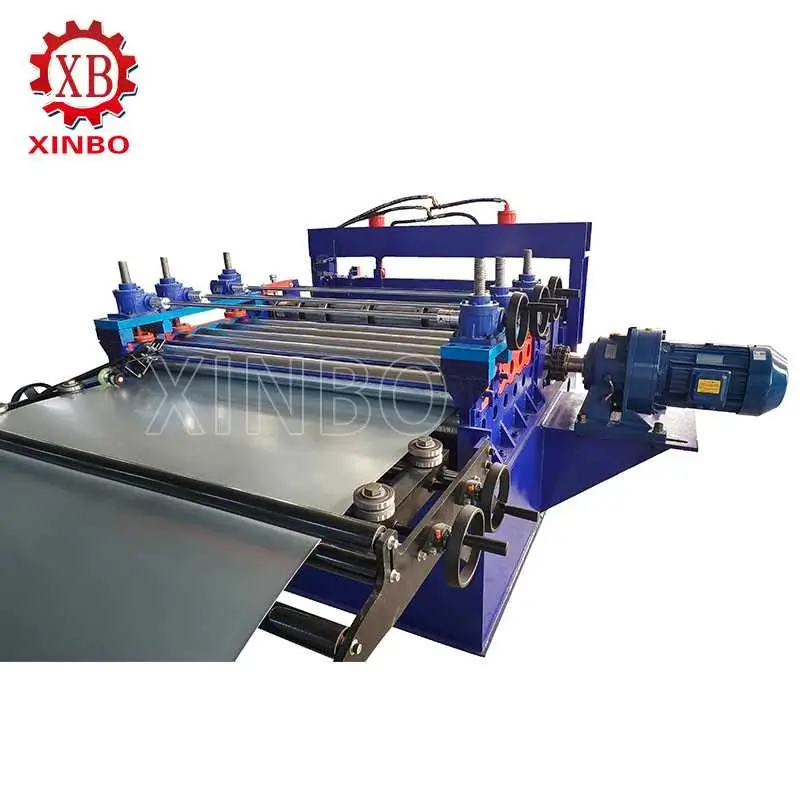

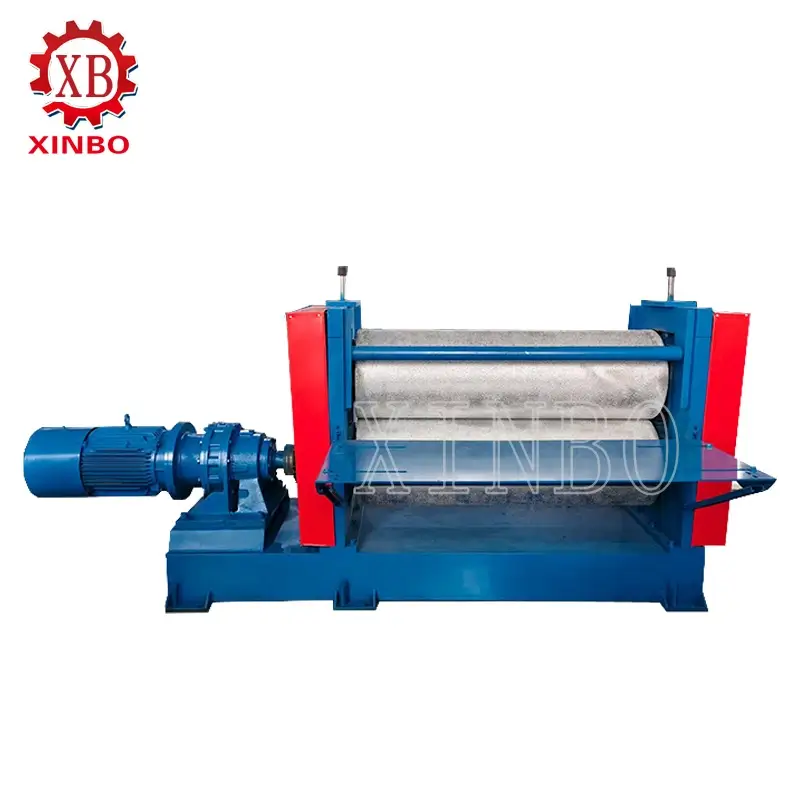

Embossing Step: Carved rollers, made of tough steel or carbide, grab the sheet. Speed controls adjust from 5-30 meters per minute. They apply 50-200 tons of pressure. For diamond or checker patterns, common in China embossing machines for metal plates, rollers make interlocking textures. These improve slip resistance.

-

Cooling and Checking: After embossing, cooling fans may steady the metal. Sensors spot flaws and stop the machine if needed. This ensures perfect results.

-

Winding and Output: The finished plate winds onto a recoiler. It’s ready for cutting or more work. Some machines stack flat plates for easy use.

Safety stuff like emergency stops and overload protection is standard. They meet CE and UL rules. Energy-saving servo motors cut power use by up to 30% compared to old hydraulic models. For custom jobs, you can upload designs via USB or Ethernet. This lets you tweak things on the go.

For example, a machine might turn 1mm stainless steel into non-slip treads for factory stairs. The result? Plates with 0.5-1mm deep embossing that last through 50,000+ uses.

Benefits of Using Automatic Metal Embossing Machines

Getting an automatic metal embossing machine brings big wins for speed, quality, and savings.

-

Faster Work: Automation skips handwork, making five times more than half-manual systems. Great for factories producing 1,000+ square meters a day.

-

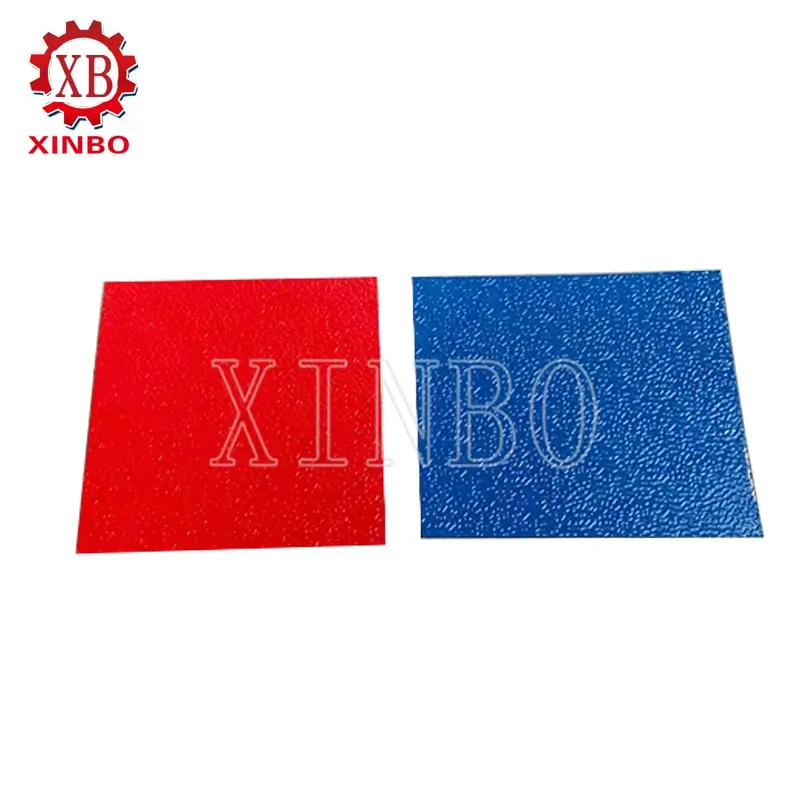

Tough and Pretty: Embossed designs make surfaces 20-30% harder through work-hardening. They also look cool for branding. For car VIN plates, this keeps them readable for years.

-

Works with Many Metals: Use aluminum for light panels, brass for fancy trim, or carbon steel for heavy jobs. Chinese models handle up to 3mm thick metals without changing tools.

-

Saves Money: Less than 1% scrap and fewer workers cut costs by 40%. Plus, XINBO’s container-friendly designs lower shipping costs for buyers abroad.

-

Green Bonus: Precise controls cut waste, meeting ROHS and REACH rules for eco-friendly production.

From oil plants labeling valves to furniture makers adding textures, these machines make work easier and products better.

Key Features to Look for in Top Embossing Machines for Metal

Picking the right embossing machine for metal means checking features that fit your needs, materials, and budget.

-

Strong Build: Choose machines with welded steel frames for 24/7 use. Look for ones handling 1250mm widths and 0.3-3mm thicknesses.

-

Automation Level: PLC touchscreens store up to 100 patterns. Auto-alignment with photoelectric sensors keeps things consistent.

-

Custom Options: Swap rollers for patterns like linen, coin, or logos. Add roll-forming for full production lines.

-

Accuracy and Speed: Get designs as fine as 0.1mm. Speeds hit 25m/min. Frequency drives stop slips on oily sheets.

-

Certifications and Help: Look for UL, CE, TUV, and CQC marks for safety. Choose suppliers with ODM services for custom designs.

For China embossing machines for metal plates, energy-saving inverters and easy-to-fix parts make upkeep simple, often with 1-year warranties.

Spotlight: Top China Embossing Machines for Metal Plates

China makes awesome automatic metal embossing machines. They mix low cost with top tech. Here are some great models, inspired by leading designs, focused on plate processing.

-

High-Speed Sheet Embosser (1m-1.5m Width Models): These handle stainless and galvanized plates up to 1.5m wide. They make diamond checker patterns at 15m/min. They have hydraulic uncoilers and auto-recoilers, great for building treads. With 100-ton force, they create 1mm-deep embossings that pass salt-spray tests for rust resistance.

-

CNC Precision Plate Embosser: Made for custom designs, it uses CAD software for direct pattern uploads. It works with aluminum and steel up to 2mm thick. Servo-driven rollers give super precise results. Output: 500-800 plates/hour, perfect for signs or car nameplates.

-

Integrated Roll-Forming Embosser Line: A full setup that embosses and shapes in one pass. It turns coils into textured panels, saving 25% on shipping with 40ft container fit. Speeds reach 20m/min, with leveling for flatness under 1mm/m.

These machines from XINBO focus on ODM customization. They can add cold-rolling for smooth use in existing lines, meeting IEC standards.

Applications of Automatic Metal Embossing Machines

China embossing machines for metal plates are used in many industries:

-

Building: Non-slip floors and fancy facades. Embossed aluminum handles tough weather.

-

Cars: VIN tags and trim panels that resist shakes and chemicals.

-

Factories: Equipment labels in power plants. Brass embossings handle high heat.

-

Furniture and Decor: Textured stainless sheets for tabletops, adding style without extra weight.

Embossing boosts usefulness—grip improves 50% for safety—while allowing custom designs.

Maintenance Tips for Longevity

To get the most from your machine, regular care is key:

-

Clean rollers weekly with gentle cleaners to stop buildup.

-

Oil hydraulic parts monthly. Check seals for leaks.

-

Calibrate sensors every three months using maker tools.

-

Store in dry places to avoid rust on unused parts.

With good care, expect 10+ years of use, with quick support from suppliers.

FAQ

What materials can an automatic metal embossing machine process?

Most handle stainless steel, aluminum, galvanized steel, brass, and copper plates from 0.3mm to 3mm thick.

How fast is production on a China embossing machine for metal plates?

Speeds go from 10-25 meters per minute, making 300-1,000 plates per hour based on pattern detail.

Are these machines customizable?

Yes, ODM services let you customize rollers, patterns, and setups to fit your needs.

What certifications should I look for?

Check for UL, CE, TUV, CQC, ROHS, and REACH for safety and green standards.

How much does an automatic metal embossing machine cost?

Basic models start at $20,000. Advanced lines go up to $100,000, depending on capacity.

Partner with XINBO for Your Embossing Needs

Ready to boost your metal work? XINBO, a trusted Chinese maker since 2014, specializes in cool automatic metal embossing machines and roll-forming solutions. With ODM know-how, we tailor machines to your needs. They fit 20ft or 40ft containers for cheap shipping. Our team ensures IEC-compliant quality, backed by UL, TUV, CE, CQC, ROHS, and REACH certifications. Visit XINBO Homepage to see our range, Services Page for ODM details, or About Us to learn our story. Ask for a free quote now—let’s work together!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia