Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

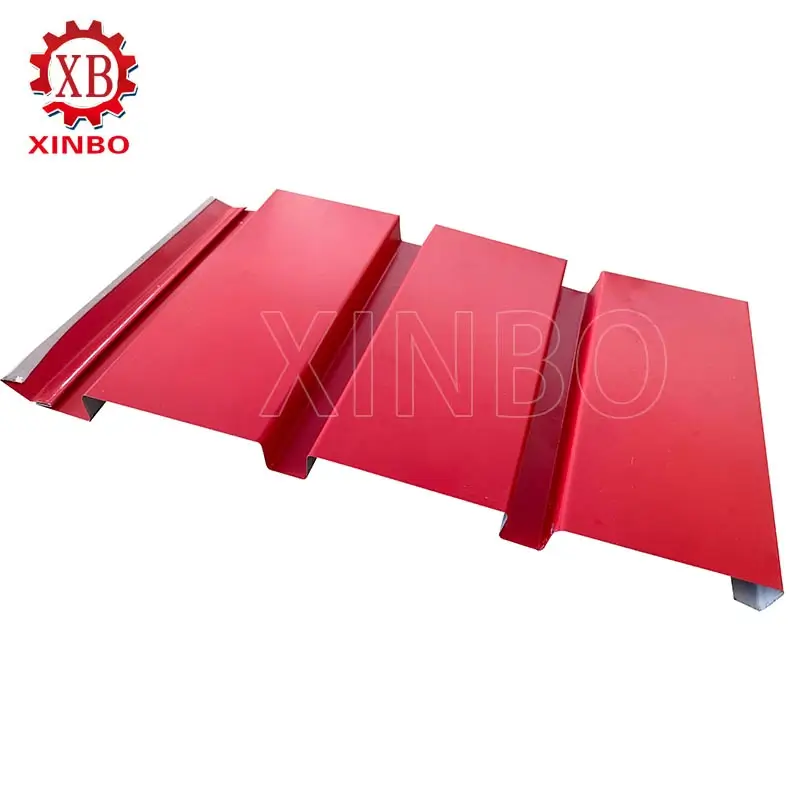

VIEW MORE→Architectural metal cladding wall panels are slim layers of metal, often made of steel or aluminum, shaped into unique designs for covering the outside or inside of buildings. These panels have a dual role in today’s building projects. They shield structures from harsh weather like rain, strong winds, and harmful sun rays while also making them look attractive.

Some important traits are:

Strength: Crafted from materials that resist rust, these panels last a long time with little upkeep.

Visual Variety: They come in many shapes, shades, and textures, such as shiny metallics, wood-like patterns, and even designs with tiny holes.

Light Build: With a thickness between 0.3 mm and 1.2 mm, they’re simple to move and set up.

Fire Safety: These metal sheets help stop fires, adding extra protection to buildings.

Thanks to these qualities, architectural metal cladding wall panels are a top pick for builders who want long-lasting and good-looking building covers.

Metal cladding panels can be grouped by how they’re used and their style:

Single Skin Panels: These are budget-friendly, shaped panels made tougher with wavy patterns. You can get them with visible or hidden fasteners.

Insulated Metal Panels: Made of two metal sheets with foam stuffed in the middle, they keep heat in and weather out very well.

Modular Panels: Easy to adjust in size and look.

Decorative Panels: Used inside buildings, they have grooved or bumpy designs to boost the style.

Popular shapes include wavy, box-like, straight-lined, and board-and-batten types.

Metal cladding wall panels fit into many different places:

Residential Construction: Used as outer walls that are tough and look nice.

Commercial Buildings: Perfect for smooth, modern-looking fronts.

Industrial Structures: Great for warehouses and factories because they’re super strong.

Agricultural Buildings: Just right for barns and sheds that need to stand up to bad weather.

Interior Design: Used on walls in offices or shops to give a fresh, trendy vibe.

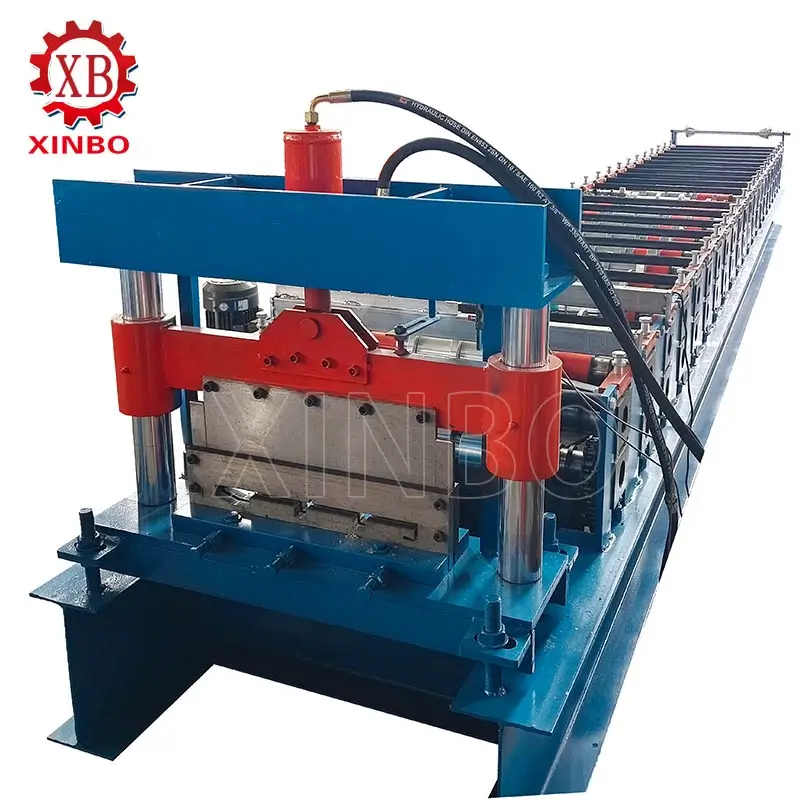

Roll forming is a steady process that turns metal rolls into exact shapes using a set of rollers. The machines for this job are very specific and built for purpose.

A common roll forming machine for metal siding cladding wall panels has these parts:

Decoiler

Guiding & Leveling System

Roll Forming System

Hydraulic Cutting System

PLC Control Box

Finished Panel Receiving Table

Extra add-ons can include auto-stackers and tools for making decorative holes.

Today’s roll forming machines come with cool perks to speed up work and improve results:

Fast output (20–60 m/min)

Works with various materials (aluminum/steel/galvanized coils)

Automatic control using PLC systems

Sharp tools for steady quality

When picking the right metal siding cladding wall panel roll forming machine, think about a few things. Go for a machine with a speed (like 20–60 m/min) that fits your work pace. Make sure it can handle stuff like galvanized steel or aluminum up to 1.2 mm thick. Also, check for handy features like PLC control systems with touch screens. Bonus tools such as follow-cutting systems or auto-stackers can make things even smoother.

Putting money into a top-notch roll forming machine can really help a wall decoration business by:

Improving the quality and sameness of products

Cutting down on worker costs with automatic setups

Allowing special designs for different jobs

Matching global rules (like CE certification)

The wall decoration field grows with fresh ideas, good quality, and quick work. Using strong roll forming machines helps companies give tailored options for homes, shops, factories, and farms.

To get the most out of your investment, try these tips. Provide custom services by making unique shapes and looks for special customers. Use eco-friendly stuff like recyclable materials. Grow into new areas by aiming at various building types.

For home projects, a wall decoration company used a fast roll forming machine to create hidden fastener panels for a new neighborhood. In farming, some firms have relied on these machines to build tough siding for barns.

Usual details include:

Raw Material: Galvanized steel, aluminum, or pre-painted coils

Material Thickness: 0.3–1.2 mm

Production Speed: 20–60 m/min

Roller Material: No. 45 hardened steel

Power Supply: 35–40 hp motor

Control System: PLC + Touch Screen

Cutting Mechanism: Hydraulic system

Warranty Period: 12–24 months

Certifications: CE compliant

Machines might come with:

Cassette-Type Platforms

Follow-Cutting Systems

Perforation Presses

Auto Stackers

These extras make the machines more adaptable and useful.

The worldwide demand for metal siding cladding wall panel roll forming machines is pushed by:

Growing cities

Need for eco-friendly options

New tech like smart controls

Important points when picking suppliers:

Years of Work & Trust

Ability to Customize

Help After Purchase & Training

Shipping Times (usually 30–45 days)

Following CE/SGS rules

Q1: How fast do these machines usually run?

A: They go from 20 to 60 meters per minute based on the type.

Q2: Can I make my own panel designs?

A: Yes. The machines can handle custom shapes and sizes.

Q3: What materials work with them?

A: Galvanized steel, aluminum sheets, or pre-painted coils from 0.3 mm to 1.2 mm thick.

Q4: Are these good for small companies?

A: Yes. Some models are small but still strong enough for big production.

XinBo machine making company is a full-on manufacturer started in 2014. We promise top-quality machines and new ideas, thanks to our skilled engineers, technicians, and workers.

XinBo’s products cover:

metal roof sheet roll forming machines

roller shutter door forming machines

door frame roll forming machine

glazed tile roll forming machine

C U channel roll forming machines

They sell to over 30 countries like the UK, Poland, UAE, USA, Brazil, and Nigeria, with CE-certified gear built to European rules.

Our expert design team crafts machines based on what customers want. “Dedicated, united, innovative, mutual benefit” is our motto. For questions or custom needs on any kind of machine, feel free to reach out.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→