Best Double Layer Roof Panel Roll Forming Machine for Glazed Tile & Corrugated Steel Roofing

In today’s tough metal roofing production setting, manufacturers always search for tools that provide top yield with least area and cost. The double layer roof panel roll forming machine has grown into a key option for factories creating both attractive glazed tile shapes and affordable corrugated steel roofing sheets on one production line.

What Is a Double Layer Roof Panel Roll Forming Machine?

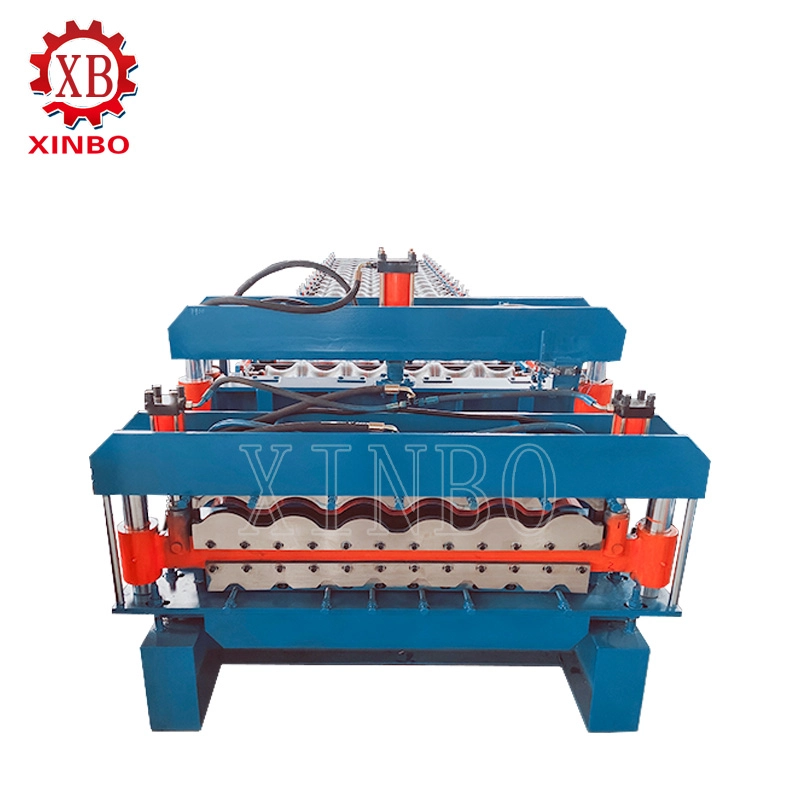

A double layer roof panel roll forming machine is a solid cold roll forming setup built with two distinct roller groups placed upright on a single base. This two-part setup permits making two varied panel shapes—generally one on the top part and one on the bottom part.

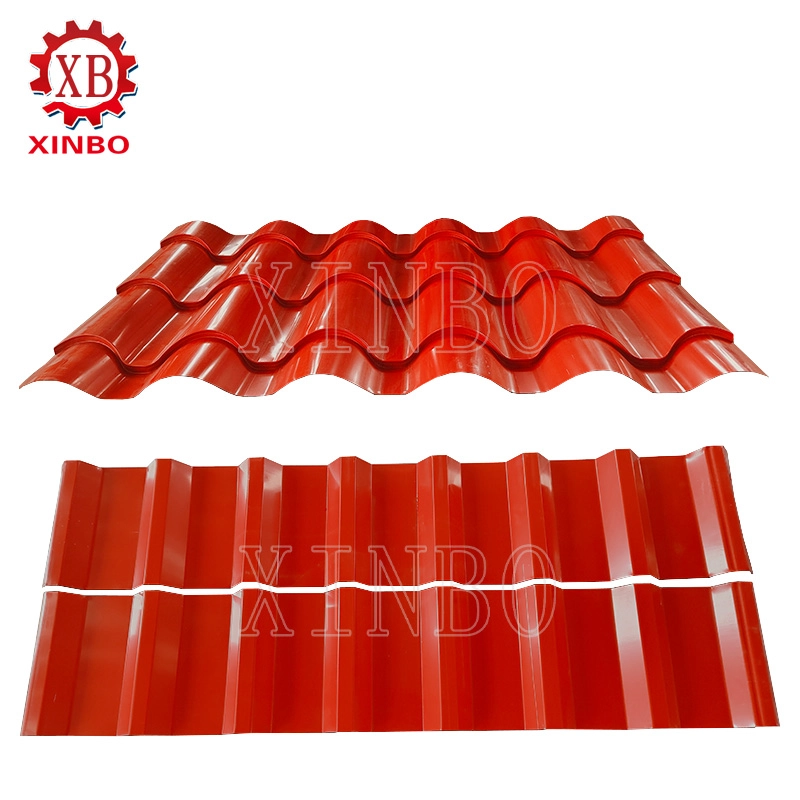

Single-layer machines stay stuck to just one shape. But this tool boosts factory floor area and cuts startup cost. Typical mixes feature glazed tile (with ridge-like pressed designs for visual charm) on one part. And they feature corrugated steel roofing (basic curved layout for build firmness) on the other. The machine turns flat metal rolls into complete roofing sheets via steady curving. It skips heat use. So, it guards material soundness.

The build usually covers a firm welded steel base. It includes exact-cut rollers. It has push setups for slicing and squeezing. And it has a solid power control setup. Many versions show clear push lifts. They use looped pipes for liquid flow. And they have a main control box for easy work.

Key Components and Structure of the Double Layer Roof Forming Machine

Grasping the parts aids in valuing the build skill behind these tools.

1. Decoiler (Uncoiler)

The flow starts with a hand or auto uncoiler. It grips the metal roll (mostly 0.3-0.8mm thick). And it sends it steadily into the tool. This avoids material twist.

2. Feeding and Leveling System

A line of rollers evens the roll. It directs it precisely into the shaping area. Thus, it lessens strain. And it secures even panel standard.

3. Dual Roll Forming Stations

The main trait: two standalone roll forming parts. The top part often manages tougher shapes like glazed tile. It adds squeeze steps for ridges and stamps. The bottom part usually shapes easier corrugated lines. Rollers come from fine stuff like Cr12Mov or GCr15. They undergo heat process for toughness (HRC 58-62). And they get chrome coated for lasting use.

4. Hydraulic Cutting System

After shaping, a push cutter slices panels to precise sizes. Certain versions add early slicing or quick cuts for better rates.

5. PLC Control System with Touchscreen

Current double layer roofing sheet roll forming machine units have user-friendly PLC links. Workers choose the needed part (top or bottom) through the display. They tweak settings like size, count, and production pace. So, this removes hand resets.

6. Runout Table and Optional Accessories

Complete panels leave to a catch table. Better plans might add auto stackers for better flow.

The upright pile plan holds the area tight. Yet it yields expert-level results.

Why the Double Layer Roof Forming Machine Is Reshaping Roofing Sheet Production

The key new feature of this tool rests in its upright two-part build. It avoids running two distinct roll forming lines next to each other. Instead, the double layer roof sheet roll forming machine piles two full forming groups one atop the other — they share the same strong central base. They also share the drive setup. They share the push unit. And they share the power box.

This smart plan offers prompt gains:

- Reduces factory floor space requirement by 40–55% compared to two independent machines

- Lowers total capital investment significantly

- Simplifies maintenance to one centralized system

- Allows quick profile switching without major mechanical reconfiguration

Understanding the Dual-Layer Workflow: One Layer at a Time

A usual mix-up holds that a double layer roofing sheet roll forming machine can create two varied shapes at once. But in truth, the tool runs just one part at any point.

Workers pick either the top part or bottom part via the touch PLC link. After the make run for the picked shape finishes, the setup halts. The material roll swaps if required. The part changes on the guide board. Then production picks up with the next shape.

This step flow guarantees:

- Zero interference between the two profile geometries

- Perfect dimensional accuracy on both products

- No compromise on forming speed or cutting precision

Core Structural Advantages of Modern Double Layer Roof Sheet Machines

Today’s double layer roof sheet machine plans add a few build tweaks. These tweaks boost dependability and simple handling in big ways.

Heavy-duty portal frame construction

Most solid tools use 350–450 mm thick welded H-beam wall sheets with complete support bars — this forms great firmness that blocks shake even at peak pace and roll span.

Independent hydraulic pressing stations

For glazed tile production (normally set on the top part), special push stamp and ridge-squeeze units form the clear deep-ridge look. Regular corrugated tools cannot match this.

Precision roller material and heat treatment

Top tools use GCr15 or Cr12Mov steel rollers. They get vacuum heat-fixed to HRC 58–62. Then they receive hard chrome layer. This mix offers 5–10 years of service life with little wear. It holds true even for 0.8 mm thick strong steel processing.

Typical Profile Combinations You Will Encounter

Most factories select these common matches when getting a double layer roof panel roll forming machine:

- Upper layer → Glazed tile / Roman tile / Venice tile (stepped, decorative profiles)

- Lower layer → 762 mm, 840 mm, 914 mm or 1000 mm corrugated wave sheets

Other regular mixes include:

- Trapezoidal profile + glazed tile

- Standing seam + corrugated

- Tile-effect metal sheet + 5-wave / 7-wave corrugated

The option to pair two shapes that move well in one area makes the odm double layer roof roll forming machine quite appealing for local manufacturers.

Real-World Production Efficiency Numbers

Current tools with 18–24 forming stations per layer often reach:

- Glazed tile profiles: 6–12 meters per minute (depending on step depth and pressing frequency)

- Corrugated profiles: 15–28 meters per minute

- Average daily output (8-hour shift, including coil changes and layer switching): 4,000–9,000 linear meters

Add the skill to change shapes without buying another full production line. Then the payback on cost turns quite strong.

Important Details That Affect Long-Term Performance

Servo motor vs hydraulic motor drive

Fresh tools more often employ full AC servo chief drive setups over old push motors. Servo setups deliver:

- More precise length control (±1 mm)

- Smoother acceleration/deceleration

- 15–25% lower power consumption

- Quieter operation

Automatic stacker integration

Many mid-to-high-end double layer roof forming machine lines now provide fitted auto sheet stackers. These stack done panels tidy without hand effort — a major labor expense cut for long roll runs.

Quick-change cassette option

Certain forward manufacturers provide box-type roller groups for one or both parts. This permits quicker shape swaps when creating over two standard items.

FAQ

Q1: How long does it typically take to switch from one layer to the other?

Between 5–20 minutes depending on operator experience, coil change requirement, and whether material needs to be re-threaded.

Q2: Can the same coil thickness be used on both layers?

Yes — most machines are designed to handle the same thickness range (usually 0.3–0.8 mm) on both layers without adjustment.

Q3: Is servo drive worth the extra investment?

For factories producing high-value glazed tiles or requiring very tight length tolerance (±1 mm), servo drive usually pays back within 12–18 months through reduced scrap and higher selling price.

Q4: How many years of service life can I realistically expect?

With proper maintenance and quality components: 8–15 years of single-shift operation is common.

Q5: Can I add more profiles later?

Yes — most manufacturers offer additional roller sets or even cassette systems that can be added after initial purchase.

Ready to Move Your Roofing Sheet Production Forward?

If a factory requires dependable, strong-yield tools able to create both fine glazed tile and sought-after corrugated roofing smoothly, the double layer roof panel roll forming machine stands as one of the sharpest options open now.

XINBO focuses on crafting sturdy, simple-to-use double-layer systems planned for steady long-run work and direct handling. The XINBO team has supplied hundreds of these tools to roofing manufacturers globally. And it can offer thorough tech advice, shape sketches, production setup tips, and after-sales service.

Reach the XINBO team today to review a certain shape mix, factory area, and goal yield — and learn how a fine-tuned double layer roof sheet roll forming machine can shift production flow and earnings.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia