Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

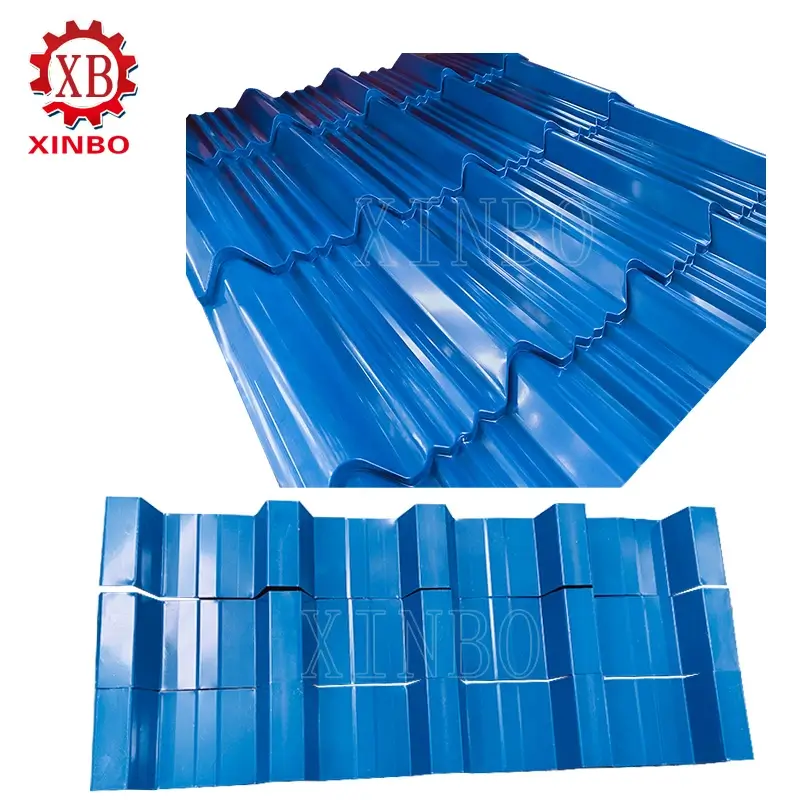

VIEW MORE→If someone seeks a double layer roof panel roll forming machine, a double layer roofing sheet roll forming machine, or a double layer roof sheet roll forming machine, this spot fits perfectly.

These flexible tools change how factories create roofing items. They provide two-profile options in one small setup.

People might want an advanced double layer roofing machine for exact results. Or they might pick an affordable double layer roofing machine to match funds. This guide looks closely at key points.

As factory needs rise—such as for storage buildings, plants, and business structures—picking proper gear can help or hurt the workflow.

In this full buyer’s guide, the text checks basic parts of automatic double layer roof sheet forming machines. It covers their usual uses and hints for picking the best double layer roofing machine.

The guide also includes:

Buying a double layer roofing machine

Choosing the right double layer roofing sheet roll forming machine

Why a cost-effective or customized double layer roofing machine could become the next wise choice

By the finish, clear facts will help make a smart pick that raises output without extra expenses.

At its heart, a double layer roof panel roll forming machine serves as an auto setup. It builds two different roofing sheet shapes at once from one metal roll.

Unlike old single-layer units, this two-deck plan has an upper and lower shaping spot. It allows easy shifts between shapes. Examples include wavy sheets for strength and angled panels for nice looks.

Material Feeding: The task starts when a metal coil—often galvanized steel, aluminum-zinc mixes, or pre-painted sheets—goes into a decoiler.

Leveling: The item moves through rollers to stay flat.

Forming: Carefully built rollers mold the sheet into the wanted shape.

Cutting: A hydraulic cutting tool slices the sheets to set lengths.

Output: A stacker or runout table gathers the ready goods.

This steady, fast action cuts waste and boosts amount. It often hits 20–30 meters per minute.

The compact build—two work lines in one area—lowers plant space fees and eases growth.

New types add PLC systems with touch screens, auto fault checks, and safety marks like CE or ISO certification.

In short, double layer roofing machines link flexibility and speed. They become vital for industrial roofing sheet makers.

Learning the workings of a double layer roof sheet roll forming machine shows its smart design.

Hydraulic or manual uncoilers manage 8–10 ton coils.

Tension control stops feed errors.

Pinch rollers smooth out flaws.

Guide rails keep shape exact (±0.5mm).

15–25 stations per layer, with chain or gear drives.

Dual layers use one motor; clutches handle tasks.

Optional embossing, punching, and hydraulic shearing.

Programmable length cuts (1–12m).

PLC watches and changes speed on its own.

Hydraulic lift tables grab finished sheets.

An advanced double layer roofing machine with servo motors can change profiles in moments. It cuts stop time by up to 70% and reaches 10,000 meters per shift.

The double layer roof panel roll forming machine shines in many fields.

It works for storage roofs and plant walls. Wavy profiles give strong yet light builds.

It suits malls, clinics, and offices. Auto systems make linking panels for better warmth (cutting HVAC fees by 15–20%) and quicker setup.

Light, adjustable roofing sheets copy tile looks while lowering weight. They fit new houses and fixes.

Galvanized results cover barn roofs and frame covers. Tough wall panels go in bridges and tunnels.

Environmentally, these setups aid green making. They back metal reuse and eco marks like LEED.

When buying a double layer roofing machine, think about these main parts:

Frame Quality: Welded steel (20mm+ thickness) for lasting use

Rollers: Chrome-plated 45# steel, hardened to HRC 58–62

Automation: Full PLC + HMI touchscreen, Ethernet-enabled

Speed: 0–60m/min variable drive

Material Range: 0.3–0.8mm thickness, up to 1250mm width

Safety: CE-certified, auto-lubrication, dust extraction

Efficiency: Energy-saving inverters reduce power draw by 30%

For affordable double layer roofing machines, seek modular builds. They allow adds like stacking robots or extra stations.

Picking the proper machine means matching output aims, size, and funds.

Production Volume:

Basic models for <5,000m/day

Automatic systems for high-output operations

ROI:

A cost-effective double layer roofing machine returns in 12–18 months via 20–30% labor cuts.

Customization:

Support for CAD-based profiles, variable voltages (220V–480V), and containerized delivery.

Space & Power:

Standard footprint 10–15m; power 15–30kW.

After-Sales:

Choose suppliers with training, spare parts, and warranties (1–2 years).

Affordable does not mean poor quality. These units mix price and work through shared hydraulics and smart control setups.

Expect:

25–40% lower start cost

Noise-cutting chain drives

98% production yield

2-year warranty options

Modular tooling for growth

Over years, bearing life past 1 million cycles and power-smart drives turn them into a clever long choice.

Keep the unit at top work:

Clean rollers and guides

Check and add lubrication (every 8 hours)

Confirm alignment (±0.1mm)

Look at hydraulic fluid levels

Watch PLC logs

Swap worn belts or seals

Fix bearings

Set cutters

Train workers for early checks

With steady care, the best double layer roofing machine can run well for 15+ years.

With these facts, buying a double layer roofing machine turns into a planned step.

Balance output amount, shape variety, and funds to pick a setup that grows with future needs.

Test runs and ROI checks make sure the customized double layer roofing machine fits tech and money goals.

Q1: What is the main advantage of a double layer roofing sheet roll forming machine?

It produces two profiles in one compact unit, reducing factory footprint by up to 50% and cutting investment costs.

Q2: How fast can an automatic double layer roof sheet forming machine operate?

Typically 20–30 meters per minute, depending on material and profile complexity.

Q3: What materials are compatible?

Galvanized steel, galvalume, pre-painted coils, and aluminum (0.3–0.8mm thickness).

Q4: How do I choose between affordable and advanced models?

Affordable options suit low-volume production; advanced models excel in precision, automation, and rapid changeovers.

Q5: What maintenance ensures long life?

Regular cleaning, lubrication, calibration, and timely part replacement minimize downtime and extend lifespan.

Don’t let old gear hold back potential.

As a leading China double layer roofing machine manufacturer and supplier, XINBO delivers customized, cost-effective, and automatic double layer roof sheet forming machines designed for industrial excellence.

📞 Contact XINBO today for a free consultation — and transform your roofing sheet production with precision, reliability, and innovation.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→