Good quality

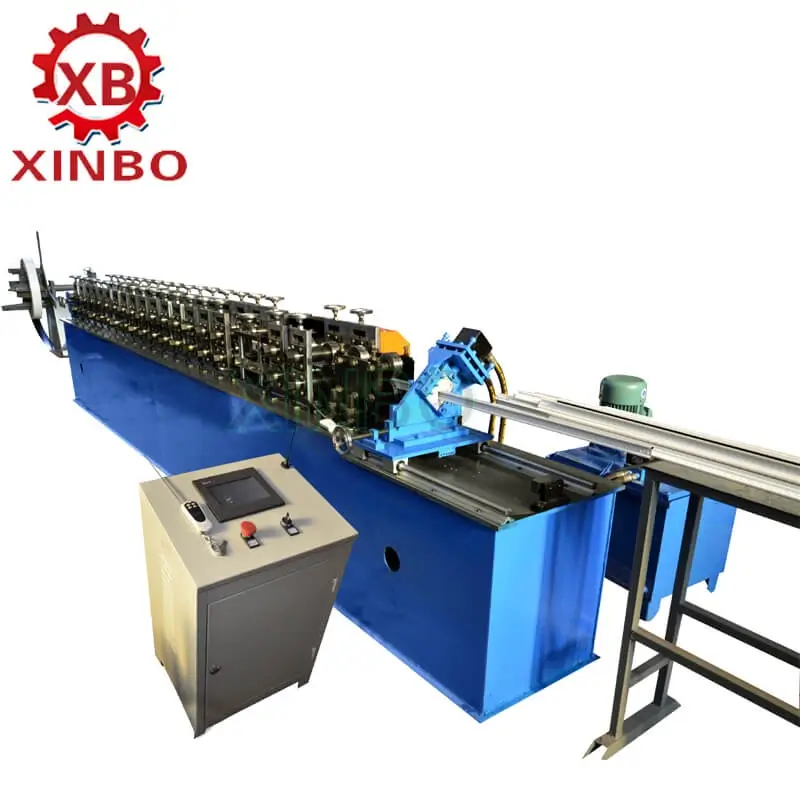

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

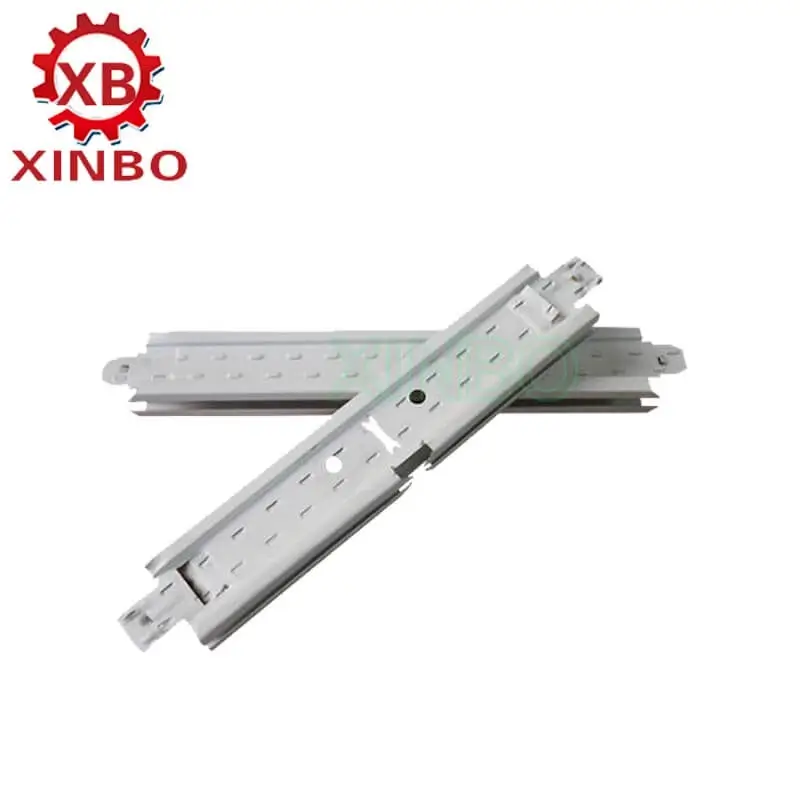

VIEW MORE→A t shape keel roll forming machine is a specialized device that shapes metal sheets into T-shaped keels for ceiling grids. These machines use a series of rollers to bend and form galvanized steel or other metals into precise profiles. The ceiling t grid roll forming machine is widely used to create strong, lightweight frames for suspended ceilings in buildings. It automates the process, ensuring consistent quality and speed. Understanding what a light keel roll forming machine does helps businesses choose the right equipment for efficient production.

T grid machines are essential in construction, especially for commercial and residential buildings. They produce ceiling T-bars and wall angles for suspended ceilings, which support tiles and lighting. The galvanized steel keel roll forming machine is also used in offices, schools, and hospitals for durable, fire-resistant ceiling systems. These machines support high-volume production, making them ideal for manufacturers supplying large projects. Knowing the applications of a ceiling t bar roll forming machine helps businesses align equipment with market demands.

A top automatic grid roll forming machine offers high precision and speed. It uses PLC (Programmable Logic Controller) systems to control cutting and forming, ensuring accurate T-bar sizes. The automatic t ceiling production line reduces manual work, boosting efficiency. Precision is key for consistent keel shapes, which fit perfectly in ceiling grids. Businesses benefit from choosing a t grid making roll forming machine with advanced automation to meet strict quality standards.

A quality t bar keel roll forming machine is built to last, using strong materials like Cr12 rollers for durability. It handles galvanized steel, colored armor plates, or other metals with thicknesses of 0.2-0.6 mm. The galvanized keel roll forming machine resists wear, ensuring long-term use. Compatibility with various materials allows businesses to produce different keel types, meeting diverse client needs. Durability and flexibility are critical factors to consider when choosing a light steel keel forming machine.

The decoiler in a ceiling t grid machine unwinds metal coils, feeding them into the machine. It ensures smooth, even feeding to prevent material jams. The feeding system aligns the metal sheet for precise forming. A reliable decoiler is vital for continuous production in a t grid light keel roll forming machine, reducing downtime and ensuring consistent output for businesses.

The roll forming unit in a light keel cu purlin roll forming machine shapes the metal through rollers into T-bar profiles. The automatic cutting machine then trims the formed keels to exact lengths with smooth edges. These units work together in a ceiling keel roll forming machine to produce precise, ready-to-use keels, minimizing waste and ensuring high-quality output for large-scale projects.

The hydraulic system in a t bar ceiling keel roll forming machine powers the cutting and forming processes. It uses a gear wheel oil pump for smooth operation. The PLC control system adjusts settings like length and speed, making the omega light keel forming machine easy to operate. These systems ensure efficiency and accuracy, helping businesses meet production goals with a ceiling tee grid machine.

Setting up a light keel roll forming machine involves loading the decoiler with a galvanized steel coil. Operators check the material thickness, usually 0.2-0.6 mm, and ensure it’s free of defects. The machine is then calibrated for the desired T-bar profile. Proper setup in a china ceiling t grid roll forming machine ensures smooth operation and high-quality keels, reducing errors during production.

Operating an automatic t grid roll forming machine is straightforward with its PLC system. Operators input settings like length and speed, then start the machine. The t grid ceiling machine runs automatically, forming and cutting keels. Workers monitor for jams or errors, ensuring consistent output. Regular checks keep the light keel purlin machine factory running efficiently, meeting business deadlines.

A key factor in choosing a ceiling t bar roll forming machine is its speed, often up to 25 m/min. High-speed machines, like those from t celling keel forming machine suppliers, boost output for large orders. Businesses should match capacity to demand, ensuring the light keel roll forming machine suppliers provide equipment that meets project needs without delays.

A customizable light keel roll forming machine allows businesses to produce various keel profiles, like T-bars or wall angles. Xinbo automatic t grid ceiling light keel roll forming machine offers custom design services, tailoring machines to specific needs. Established in China in 2014, Xinbo provides ODM solutions, fast delivery, and three quality inspections. Their engineers create precise drawings, ensuring machines fit unique profiles, helping businesses meet diverse client demands with a china t shape keel roll forming machine.

Cost is a big factor when picking a t grid roll forming machine. High-quality machines may cost more but save money with low maintenance and long life. Regular cleaning and roller checks keep a light steel keel roll forming machine running smoothly. Businesses should compare initial costs with long-term savings from durable equipment offered by light keel roll forming machine companies.

A t grid machine automates production, cutting labor costs and boosting speed. The automatic t grid roll forming machine produces keels faster than manual methods, saving time. Its precision reduces material waste, lowering costs. Businesses using a ceiling t grid roll forming machine see higher profits and faster project completion, making it a smart investment.

A galvanized steel keel roll forming machine ensures every T-bar is the same, meeting strict building standards. Consistent quality builds client trust. The machine’s scalability lets businesses increase output as demand grows, supporting large projects. Choosing a reliable t grid machine company ensures equipment that delivers quality and growth potential.

It’s a machine that shapes metal into T-bar keels for ceiling grids, used in construction.

Many machines, like a ceiling t grid roll forming machine, produce up to 25 m/min.

Yes, a customizable light keel roll forming machine can make various keel profiles for different needs.

It uses galvanized steel or colored armor plates, typically 0.2-0.6 mm thick.

Choosing the best t shape keel roll forming machine can transform your business, boosting efficiency and quality. From automation to durability, the right light keel roll forming machine meets production needs and saves costs. Consider speed, customization, and maintenance to find the perfect fit. Don’t let outdated equipment slow you down—upgrade your production today! Visit cnxinbo.net to explore Xinbo’s t grid machines or contact their team for tailored advice to elevate your ceiling grid manufacturing!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→