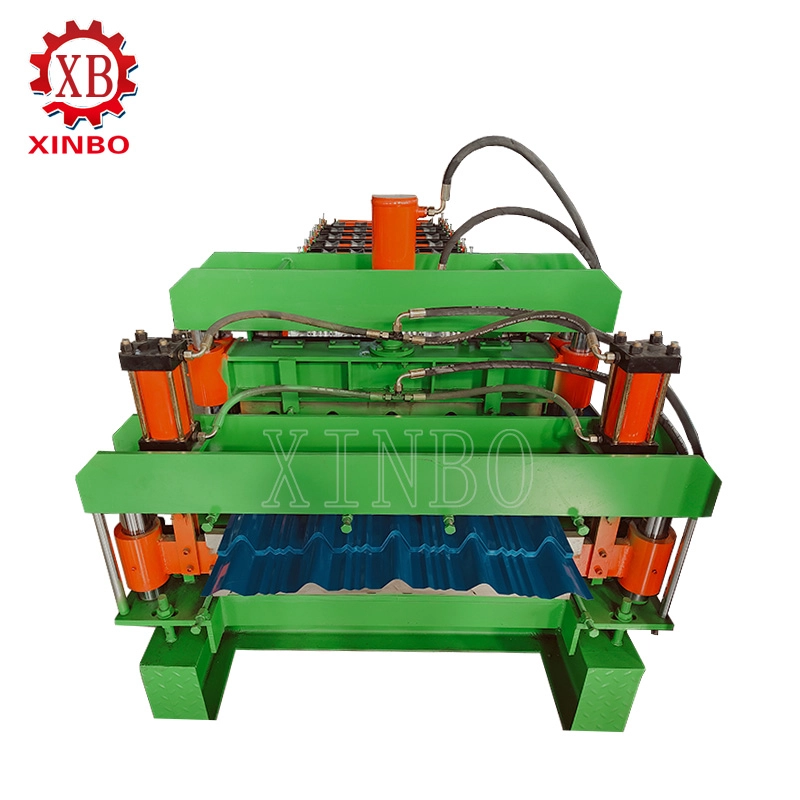

Custom ODM Double Layer Roof Forming Machine for Trapezoidal & Corrugated Sheets

In the field of metal roofing production, the double layer roof panel roll forming machine stands out as a really efficient option for makers who want flexibility without losing space or power. This modern equipment, also called the double layer roofing sheet roll forming machine, lets you make two different profiles—like trapezoidal and corrugated sheets—on just one small frame. As an ODM double layer roof roll forming machine, it provides custom designs made to fit exact project needs. This makes it perfect for creating top-quality roofing materials used in construction, factories, and warehouses.

The double layer roof sheet machine mixes strong build quality with simple operation. It allows quick switches between profiles. Whether you produce strong trapezoidal panels for good support or traditional corrugated sheets for nice looks and better water flow, this machine gives steady results.

What is a Double Layer Roof Forming Machine?

A double layer roof forming machine is a special roll forming system built to create two different metal roofing profiles in one unit. Unlike single-layer machines that work on only one profile at a time, the double-layer setup has two sets of rollers placed one above the other. They share the same drive system and frame.

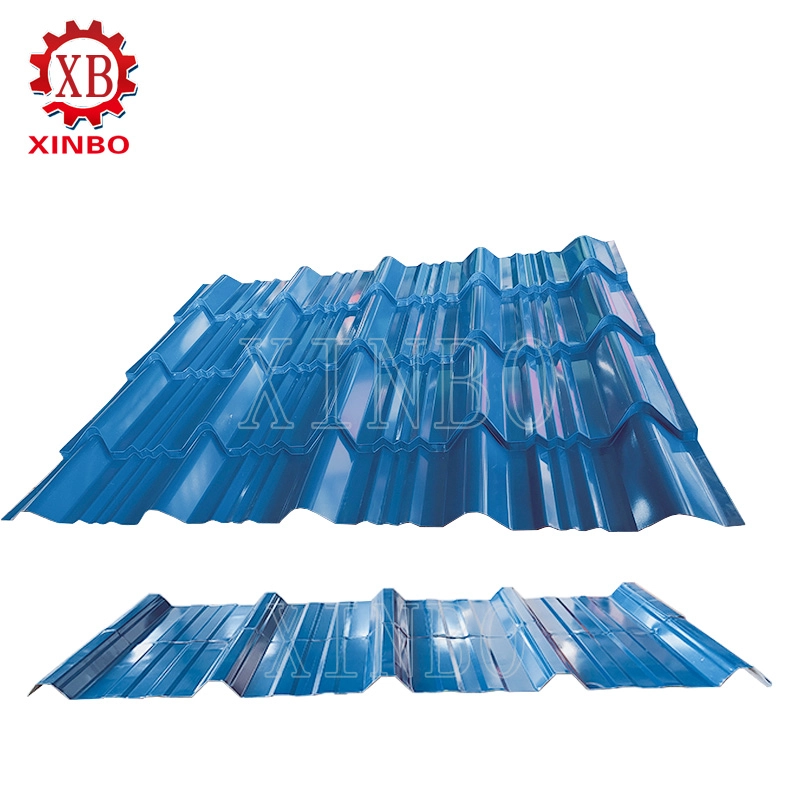

This setup works well for making trapezoidal and corrugated sheets. These are very common roofing choices because of their strength, ability to handle weather, and easy setup. The double layer roof sheet roll forming machine takes metal coils—usually PPGI, GI, or aluminum—and shapes them through bending stations into exact panels.

How Does a Double Layer Roof Panel Roll Forming Machine Work?

The double layer roof panel roll forming machine follows a clear, automatic process to keep things accurate and fast. It starts with a decoiler that unwinds the metal coil smoothly. Then the sheet goes through a feeding guide and leveling device to fix any bends or twists.

After that, the material moves into the roll forming area. It uses either the upper or lower set of rollers, based on the profile you choose. The rollers bend the sheet step by step into the right shape—for example, trapezoidal on the upper layer or corrugated on the lower one. Important point: the machine runs only one layer at a time. You pick the layer on the electrical control panel. This avoids problems and keeps the output clean and high quality.

Once shaped, a hydraulic post-cutting system—often with a flying shear—cuts the panel to the needed length. The finished sheets go to a run-out table for stacking. Newer double layer roofing sheet roll forming machines use PLC controls. These make it easy to choose profiles, set lengths, and run batches. They reach speeds of 15-25 meters per minute.

Key Components of the Double Layer Roof Sheet Machine

The double layer roof sheet machine has several main parts that help it stay reliable and perform well:

-

Decoiler: Manages coil loading with automatic tension control.

-

Feeding and Leveling System: Keeps the material straight and flat as it enters.

-

Roll Forming Stations: Two stacked sets of precise rollers (usually 13-18 stations per layer). These are made from hardened steel with chrome plating for long life.

-

Hydraulic System: Powers the cutting and any pressing tasks.

-

Electrical Control Cabinet: Comes with a touchscreen for picking the upper or lower layer, setting details, and watching production.

-

Run-Out Table and Stacker: Collects and organizes the finished panels.

These parts team up to create profiles with tight measurements, even corrugations, and a great surface finish.

Advantages of the Double Layer Roof Forming Machine

The double layer roof forming machine brings many strong benefits for manufacturers:

-

Space Efficiency: It takes up the space of one machine but handles two profiles. This is great for shops with limited room.

-

Cost Savings: It costs less than buying two separate single-layer machines. Maintenance and running costs stay lower too.

-

Versatility: You can switch between profiles like trapezoidal (for heavy loads) and corrugated (for good drainage and looks) right from the control panel.

-

High Productivity: Automatic work cuts down on stops. Profile changes happen fast, and output quality stays even.

-

Durability and Precision: The machine has a tough frame and high-grade rollers. It lasts long and forms accurately, even with different material thicknesses (0.3-0.8mm).

These benefits make the double layer roof panel roll forming machine a smart pick for growing production without needing bigger facilities.

Applications of Trapezoidal and Corrugated Sheets Produced by the Machine

Trapezoidal sheets have wide flat areas and strong ribs. They offer great support and see common use in industrial roofs, walls, and cladding. Corrugated sheets show a classic wavy pattern. They work well for water drainage and appear often in farm buildings, warehouses, and home roofing.

The double layer roofing sheet roll forming machine makes these sheets in different thicknesses and coatings. This gives good protection against rust and long life in many weather conditions. The panels stay light but strong. They help with faster setup and lower overall building costs.

Customization Options for ODM Double Layer Roof Roll Forming Machine

As an ODM double layer roof roll forming machine, customization plays a big role in meeting special needs. Makers can adjust roller profiles for particular wave heights, rib spacing, or sheet widths. Extra features like pre-shearing, automatic stackers, or better PLC systems can go in too.

The machine’s design handles various materials and thicknesses. It offers options like servo-driven cutting for extra accuracy. This flexibility lets the equipment fit changing market needs.

Maintenance Tips for Optimal Performance

To keep the machine running at its best, check rollers often for wear. Lubricate moving parts and clean out any dirt. Look at hydraulic fluid levels and electrical connections from time to time. Good training on how to switch profiles with the control panel helps avoid mistakes and makes the machine last longer.

FAQ

Q: Can the double layer roof panel roll forming machine produce both profiles simultaneously?

A: No, the machine works one layer at a time. You select the upper or lower layer on the control panel, make the needed amount, then switch to the other profile.

Q: What materials can the double layer roofing sheet roll forming machine handle?

A: It handles PPGI, GI, aluminum, and other coated steels, usually in thicknesses from 0.3mm to 0.8mm.

Q: How do I switch between trapezoidal and corrugated profiles on the double layer roof sheet machine?

A: Just pick the desired layer on the PLC interface. Feed the material the right way, and the machine uses the correct rollers.

Q: What is the typical production speed of a double layer roof forming machine?

A: Speeds range from 15-25 meters per minute, depending on profile complexity and material.

Q: Is the double layer roof sheet roll forming machine suitable for custom profiles?

A: Yes, as an ODM solution, it can be customized for specific wave designs, widths, and other requirements.

Contact XINBO for Your Custom Double Layer Roof Forming Machine Solution

Ready to improve your roofing production with a reliable double layer roof panel roll forming machine? XINBO specializes in high-quality, custom ODM solutions like the double layer roofing sheet roll forming machine for trapezoidal and corrugated sheets. Our skilled team is prepared to talk about your needs and supply a machine made just for you. It will increase efficiency and accuracy. Reach out today to check options and receive expert help from XINBO—your trusted partner in advanced roll forming technology!

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia