How Does a Slitting Line Improve Your Metal Fabrication Process?

What is a Slitting Line in Metal Fabrication?

Definition and Functionality

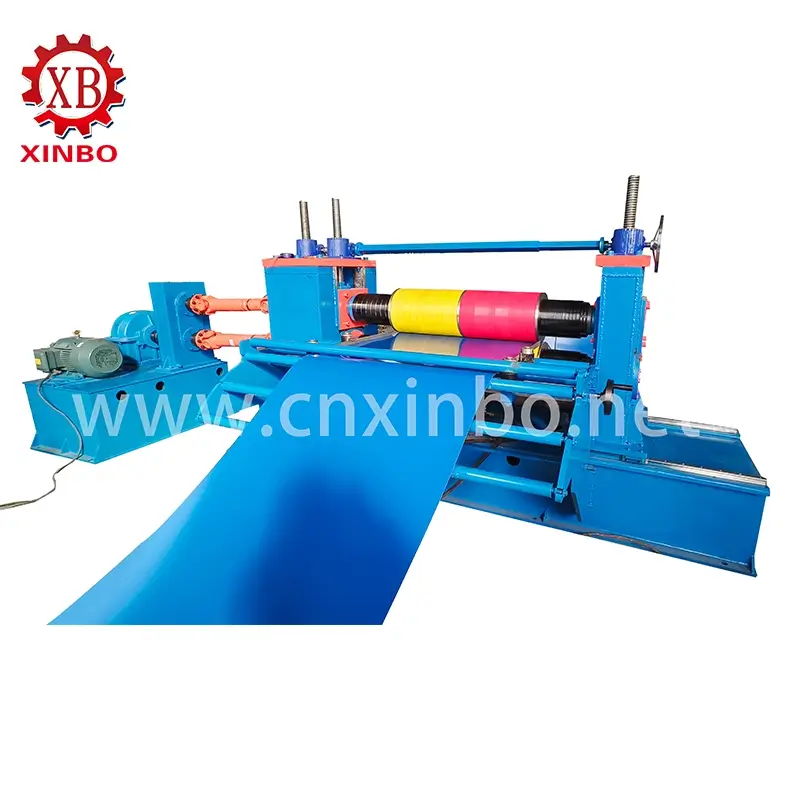

In metal fabrication processes, a slitting line plays a role as it is responsible for cutting coils of metal into narrower strips with great accuracy. The process begins with uncoiling the metal and passing it through the slitting machine where rotary knives are employed to make cuts. Finally, the slit strips are recoiled for processing or shipping. The main purpose of a slitting line is to guarantee that metal sheets are resized precisely and effectively to meet width specifications for uses.

Types of Slitting Lines

Various slitting lines cater to fabrication requirements, with differing capacities for handling materials of varying thicknesses. From light gauge lines for thinner materials to medium and heavy gauge lines designed for thicker metals. Manufacturers can select from these types based on their production needs concerning speed accuracy and material management.

How Does a Slitting Line Enhance Efficiency?

Streamlining Production Workflow

Integrating a slitting line into your operations can greatly improve efficiency by automating the cutting process and minimizing errors that may arise from intervention. This helps speed up processing times and ensures a production pace throughout cycles.

Precision and Accuracy in Metal Sheet Slitting

Attention to detail plays a role in metal fabrication work. Equipment like a slitting line is essential for achieving cutting widths to uphold the quality and specifications of products. Modern technology incorporated into these machines enables modifications and management of cutting variables leading to outcomes, for all cut strips.

What are the Economic Benefits of Using a Slitting Line?

Cost Reduction Strategies

Setting up a slitting line can result in savings, for businesses. By cutting down on waste, with cuts and lowering labor expenses through automation companies can make the most of their resources. Moreover streamlining material handling helps minimize adding to the efficiency of operations while keeping costs down.

Increased Production Capacity

Using a slitting line boosts production capacity by ensuring operation reducing the need for halts in production processes. It enables manufacturers to fulfill increased demand without sacrificing delivery schedules or product standards The flexibility provided by such lines fosters business expansion. Enhances competitiveness in the market.

How Does a Slitting Line Improve Product Quality?

Consistency in Product Output

Ensuring consistency is crucial for upholding a brand’s reputation and keeping customers satisfied in the run. A slitting line plays a role in maintaining product dimensions to meet strict quality standards for each batch produced. This uniformity fosters trust with customers who depend on specifications, for their needs and uses.

Reducing Defects and Errors

Automating the cutting process through the use of a slitting line helps to minimize mistakes and imperfections that may occur when done manually by humans. The intricate engineering, behind these machines guarantees cuts every time and results in scrap rates and improved product quality overall.

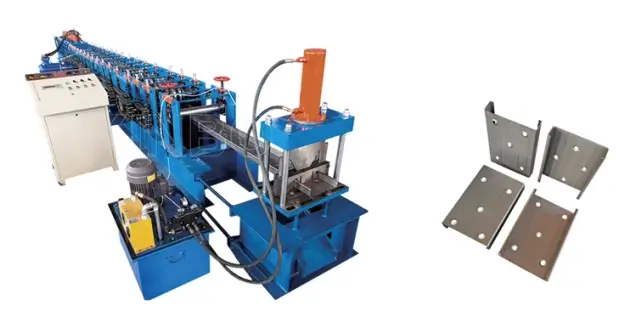

If you’re looking for top-notch metal fabrication equipment solutions XINBO MACHINE MAKING CO. LTD provides a variety of products to enhance your manufacturing operations Check them out! Their dedication to creativity guarantees you’ll get cutting-edge machinery customized for your requirements.

Why Choose XINBO MACHINE MAKING CO. LTD for Your Slitting Line Needs?

Expertise and Innovation in Metal Fabrication Solutions

When dealing with metal fabrication tasks in mind look no further, than selecting the collaborator since this can greatly impact the effectiveness of your production methods and the quality of your output goods produced by XINBO MACHINE MAKING CO., LTD. A standout figure in this field offering solutions tailored to a wide range of fabrication requirements with an emphasis, on creativity and skillfulness XINBO delivers cutting-edge equipment designed to elevate your manufacturing procedures for optimal results. Their dedication, to pushing technology means you’ll have access, to the tools needed to enhance production processes and deliver accurate outcomes efficiently.

Comprehensive Product Range and Support Services

The diverse selection of products offered by XINBO includes a range of slitting lines designed to cater to needs perfectly. If you’re in the market for a line suited for materials or one tailored for metals XINBO has got you covered. In addition to supplying machinery, Xinbo provides an array of support services like guidance on installation training sessions. Help with maintenance. This comprehensive approach ensures that you do not get top-notch equipment but also have access, to expert assistance every step of the way. To learn more about what they have available for sale, at XINBO MACHINE MAKING CO., LTD. please visit their website.

How Can You Integrate a Slitting Line into Your Existing Setup?

Assessing Current Infrastructure Compatibility

Adding a slitting line to your system involves assessing your infrastructure to ensure compatibility and effectiveness of the integration process.

Training and Maintenance Considerations

Quality training plays a role, in optimizing the advantages of a slitting line system. Equipping your team with training guarantees their proficiency in handling the equipment effectively. Moreover, consistent upkeep is key to maintaining the operation of the slitting line and avoiding disruptions. Instituting maintenance aids in the detection of possible problems and extends the durability of the machinery.

Maximizing the Potential of Your Metal Fabrication Process with a Slitting Line

To make the most of a slitting line’s benefits, in your production process, it is crucial to ensure that its functions align with your overarching manufacturing strategy. This includes establishing goals, for utilizing this equipment. Whether it is to minimize waste enhance accuracy or boost efficiency. By incorporating a slitting line into your operations you can greatly elevate productivity levels. Maintain a consistent standard of high-quality results.

To sum up the discussion; integrating a cutting line, into your metal fabrication operations provides benefits. Such as increased efficiency and cost-effectiveness well as better product standards and enhanced production capacity gains. Collaborating with players in the industry like XINBO MACHINE MAKING CO., LTD can give you access, to cutting-edge solutions that push your manufacturing capabilities ahead while keeping you competitive in the market.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia