Maximizing Output with Advanced Aluminum Window Panel Technology

How Does Advanced Aluminum Window Panel Technology Enhance Efficiency?

The Role of Aluminum Window Panel Forming Machines

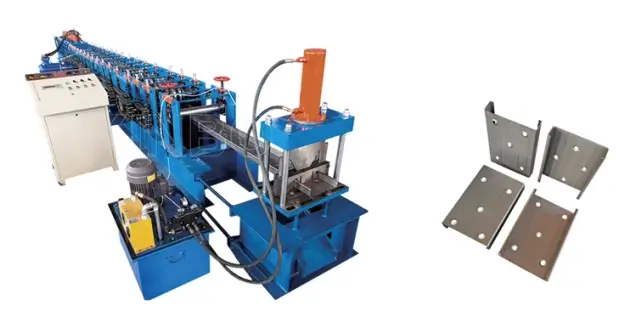

In the realm of modern construction, efficiency is paramount. Aluminum window panel forming machines play a crucial role in achieving this goal by providing precision and consistency in the production of window panels. These machines are designed to streamline the manufacturing process, reducing time and labor costs while maintaining high-quality output. By automating the shaping and cutting of aluminum panels, these machines ensure each panel meets exact specifications, which is essential for seamless installation and optimal performance in building projects.

XINBO MACHINE MAKING CO. LTD offers a range of advanced roll forming machines that cater to various construction needs. Their products, including metal roof sheet roll forming machines and door frame roll forming machines, are engineered to meet Euro standards like CE. With a commitment to innovation and customer satisfaction, XINBO provides customized solutions designed by a professional team to meet specific client requirements.

Innovations in Window Panel Design

The design of aluminum window panels has seen significant advancements, focusing on enhancing both functionality and aesthetics. Modern designs incorporate features such as improved thermal insulation, soundproofing capabilities, and increased durability against environmental elements. These innovations not only improve the comfort and energy efficiency of buildings but also extend the lifespan of the panels themselves.

Aluminum window panel forming machines are integral to realizing these design innovations. By enabling precise control over the panel’s dimensions and finishes, these machines support the creation of complex shapes and styles that align with contemporary architectural trends.

What Are the Benefits of Using Aluminum Window Panels in Construction?

Performance Advantages of Aluminum Panels

Aluminum window panels offer several performance benefits that make them an attractive choice for construction projects. Their lightweight nature reduces structural load without compromising strength or stability. Additionally, aluminum is resistant to corrosion, ensuring longevity even in harsh weather conditions.

These panels also provide excellent thermal efficiency, helping maintain consistent indoor temperatures and reducing energy consumption for heating or cooling. This characteristic makes them ideal for both residential and commercial buildings seeking sustainable solutions.

Environmental Impact and Sustainability

Sustainability is a critical consideration in today’s construction industry, and aluminum window panels contribute positively in this regard. Aluminum is a recyclable material, meaning old panels can be repurposed into new products without loss of quality. This recycling capability significantly reduces environmental impact compared to non-recyclable materials.

Moreover, using aluminum panels supports green building certifications by enhancing energy efficiency and reducing carbon footprints. Builders looking to achieve LEED certification or similar recognitions will find aluminum panels an invaluable asset.

By leveraging advanced technology in aluminum window panel production, construction professionals can maximize output while adhering to modern standards of sustainability and efficiency. For those interested in exploring further innovations in metal forming technology for construction applications, XINBO MACHINE MAKING CO. LTD offers comprehensive solutions tailored to diverse project needs worldwide.

How Can XINBO MACHINE MAKING CO. LTD Assist You?

Introduction to XINBO MACHINE MAKING CO. LTD

XINBO MACHINE MAKING CO. LTD stands at the forefront of innovation in the metal forming industry, offering state-of-the-art solutions tailored for diverse construction needs. Established in 2015, this company has rapidly evolved into a trusted name, delivering high-quality roll forming machines that adhere to Euro standards such as CE. Their commitment to excellence is evident in their extensive product range, which includes metal roof sheet roll forming machines, roller shutter door forming machines, and door frame roll forming machines.

By prioritizing customer satisfaction, XINBO MACHINE MAKING CO. LTD has carved a niche in the global market, exporting to regions such as Europe, the Middle East, Africa, and the Americas. Their professional design team collaborates closely with clients to develop customized machines that meet specific project requirements. This dedication to innovation and client-focused service ensures that each machine not only meets but exceeds expectations. For more information about their products and services, visit XINBO MACHINE MAKING CO. LTD.

Product Offerings from XINBO MACHINE MAKING CO. LTD

XINBO’s product lineup is comprehensive and designed to cater to various construction applications. From sandwich panel roll forming machines to manual decoilers and hydraulic stations, they provide everything needed for efficient production processes. These machines are known for their smart structure and reasonable design, enabling consistent output of precise shapes and sizes essential for durable construction.

Their offerings also include innovative solutions like portable metal roofing roll forming machines and light gauge steel framing machines. These products are engineered to enhance productivity while maintaining high standards of quality and reliability.

Why Should You Invest in Advanced Technology for Your Projects?

Long-term Benefits of Technological Upgrades

Investing in advanced technology brings numerous long-term benefits to your construction projects. Upgraded machinery like aluminum window panel forming machines increases production efficiency by automating repetitive tasks and minimizing human error. This leads to faster completion times and reduced labor costs.

Moreover, advanced technology ensures precision in manufacturing processes, resulting in higher quality products that require less maintenance over time. This reliability translates into cost savings on repairs and replacements, making it a financially sound investment.

Future Trends in Aluminum Window Panel Technology

The future of aluminum window panel technology is poised for exciting developments that promise even greater efficiency and sustainability. Emerging trends include enhanced automation capabilities through artificial intelligence integration and IoT connectivity for real-time monitoring of production lines.

Additionally, there is a growing focus on developing eco-friendly materials that further reduce carbon footprints without compromising performance or durability. As these trends continue to evolve, staying ahead by investing in cutting-edge technology will be crucial for maintaining competitiveness in the construction industry.

By choosing advanced aluminum window panel technology from reputable suppliers like XINBO MACHINE MAKING CO. LTD, you position yourself at the forefront of innovation while ensuring your projects meet modern demands for efficiency and sustainability.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia