Introduction to Roll Forming Machines

Roll forming machines have revolutionized the manufacturing industry, playing a pivotal role in shaping various metal components used in everyday products. A brief exploration of the history and the roll forming process sheds light on the significance of these machines.

A Brief History of Roll Forming Machines

The concept of roll forming dates back to the early days of the Industrial Revolution when manual processes were gradually replaced by mechanized methods. The first roll forming machine was developed to efficiently produce metal profiles for construction and industrial applications. Over time, advancements in technology and engineering have refined these machines, making them indispensable in modern manufacturing.

Understanding the Roll Forming Process

The Basics of Roll Forming

Roll forming is a continuous metal shaping process that involves feeding a flat sheet of metal through a series of rollers to gradually form it into a desired cross-sectional profile. This method allows for high-volume production with consistent quality, making it ideal for various industries.

Key Components of a Roll Forming Machine

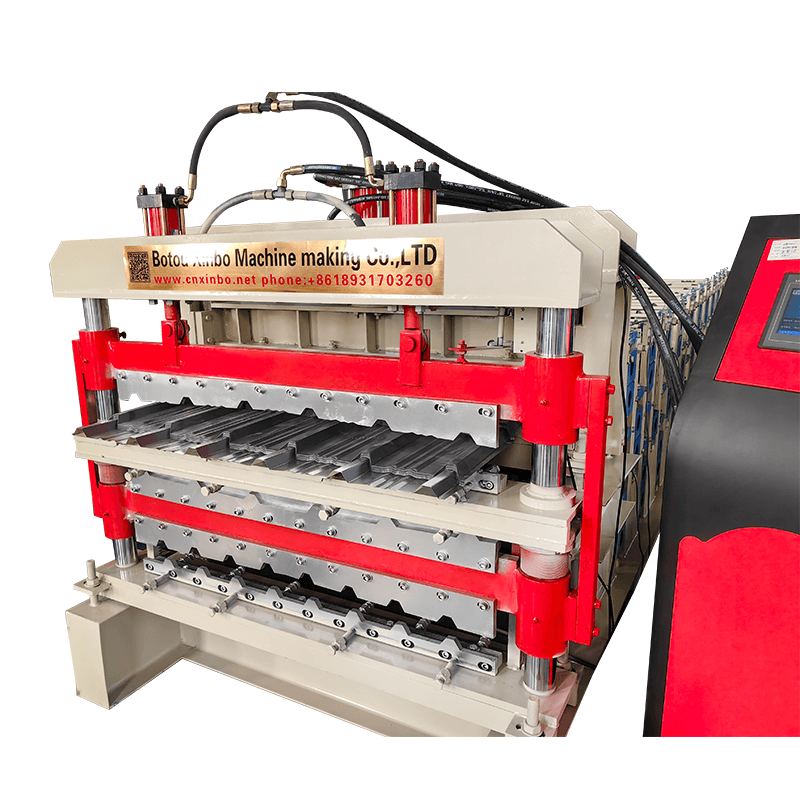

A typical roll forming machine consists of several key components, including entry and exit guides, leveling equipment, roll stands with multiple rollers, and cutting tools. These components work together seamlessly to ensure precise shaping and cutting of the metal as it passes through the machine.

By delving into the historical roots and fundamental aspects of roll forming machines, one can gain a deeper appreciation for their widespread impact across diverse industries.

The Essential Role of Roll Forming Machines in the Automotive Industry

Roll forming machines play a crucial role in the automotive industry, where precision and durability are paramount. Their applications in vehicle manufacturing extend to creating structural components and offer numerous advantages for producing automotive parts.

Roll Forming Applications in Vehicle Manufacturing

Creating Structural Components

Roll forming machines are extensively used in the production of structural components for automobiles. These components include pillars, roof rails, and floor reinforcements, which require high strength and dimensional accuracy. The roll forming machine process ensures that these components meet the stringent safety and quality standards demanded by the automotive industry.

Advantages of Roll Forming for Automotive Parts

The use of roll forming machines provides several advantages for manufacturing automotive parts. One significant advantage is the ability to produce complex shapes with consistent quality, ensuring precise fitment and performance. Additionally, the high-speed production capabilities of roll forming machines contribute to efficient manufacturing processes, meeting the demands of large-scale automotive production.

Case Studies: Roll Forming in Action

Example of a High-Performance Car

In the realm of high-performance cars, roll forming machines are instrumental in shaping specialized components such as chassis reinforcements and body panels. The exceptional strength-to-weight ratio achieved through roll forming processes contributes to the overall performance and safety features of these vehicles.

Innovations in Automotive Roll Forming

Recent innovations in automotive roll forming have focused on enhancing material utilization efficiency and reducing overall weight without compromising structural integrity. Advanced roll forming techniques enable manufacturers to create lightweight yet robust components that contribute to improved fuel efficiency and overall vehicle performance.

By understanding the pivotal role of roll forming machines in the automotive industry, one can appreciate their significance in shaping modern vehicles.

Xinbo Machine Making Co. Ltd, established in China since 2014, is a manufacturer of roll forming machines. These machines are designed with new and innovative technology to meet the needs of customers in Europe, the UK, Canada, and beyond.

Roll forming machines are used in the manufacturing industry to shape metal sheets into specific forms. Xinbo offers a variety of these machines, including U channel rolling forming machines, purlin roll forming machines, and floor deck roll forming machines.

Xinbo ensures quality assurance through a team of professional designers, producers, and workers. Each machine is inspected three times before shipping to customers to ensure all parts and profiles are as requested. Xinbo also offers custom services, with professional engineers and designers who can design detailed drawings as per customers’ needs in a short time.

How Roll Forming Machines Power the Appliance Industry

Roll forming machines are not only integral to the automotive industry but also play a significant role in shaping the production of household appliances. The versatility and precision of roll forming processes have made them indispensable in manufacturing a wide range of appliance components.

Roll Forming in Household Appliances

From Refrigerators to Washing Machines

Roll forming machines are extensively utilized in the production of various components for household appliances, including refrigerators, washing machines, and dishwashers. These machines enable manufacturers to create complex profiles and shapes required for different appliance parts with exceptional accuracy and consistency.

Benefits of Roll Forming for Appliance Manufacturing

The use of roll forming machines offers several advantages for appliance manufacturing. One notable benefit is the ability to produce parts with high structural integrity and dimensional precision, ensuring seamless integration into the final product. Additionally, the high-speed production capabilities of roll forming machines contribute to efficient manufacturing processes, meeting the demands of large-scale appliance production.

Enhancing Efficiency and Design

Custom Roll Formed Parts in Appliances

Custom roll formed parts are essential in creating unique designs and functionalities for household appliances. Manufacturers can tailor specific profiles and shapes using roll forming machines, allowing for innovative designs that meet diverse consumer needs while maintaining high standards of quality and performance.

The Role of Roll Forming in Energy Efficiency

Roll forming processes also play a crucial role in enhancing energy efficiency in household appliances. By precisely shaping metal components, roll forming machines contribute to reducing material waste and optimizing the overall design for improved energy efficiency. This results in more sustainable and environmentally friendly appliance products that align with modern energy conservation initiatives.

The Future of Roll Former Machines: Innovations and Trends

As technology continues to advance, roll forming machines are poised to undergo significant innovations and trends that will shape their future applications across various industries.

Technological Advancements in Roll Forming

Automation and Precision

The integration of roll forming machines with advanced automation technologies is set to revolutionize the manufacturing process. Automated systems will enable seamless material handling, precise tool positioning, and real-time quality control, resulting in enhanced production efficiency and consistent product quality. This advancement will streamline the entire roll forming process, reducing human intervention while ensuring unparalleled precision in shaping roll formed parts.

Sustainable Practices and Materials

The future of roll forming machines also aligns with sustainable practices and materials. Manufacturers are increasingly focusing on utilizing eco-friendly materials and implementing energy-efficient processes within the roll forming industry. Furthermore, advancements in material science are driving the development of sustainable alloys suitable for roll forming, promoting environmental responsibility without compromising the performance or structural integrity of roll formed components.

The Impact on Industries and Everyday Life

Expanding Applications of Roll Forming

The evolution of roll forming machines is expected to expand their applications beyond traditional industries such as automotive and appliances. With advancements in technology and material capabilities, roll formed profiles will find new uses in emerging sectors such as renewable energy, aerospace, and infrastructure development. This diversification will underscore the versatility and adaptability of roll forming machines, solidifying their position as a fundamental manufacturing technology across diverse fields.

Predictions for the Next Decade

Looking ahead, it is anticipated that roll forming machines will continue to play a pivotal role in shaping modern industrial landscapes. The next decade is likely to witness further integration of smart technologies into roll forming processes, enabling real-time data monitoring, predictive maintenance, and adaptive control systems. Additionally, ongoing research into innovative materials and design methodologies will drive the development of highly specialized roll formed products, catering to evolving market demands for customized solutions.

Conclusion: The Ubiquitous Impact of Roll Forming Machines

Summarizing the Importance of Roll Forming

The widespread utilization of roll forming machines across diverse industries underscores their pivotal role in shaping modern manufacturing processes. From automotive to appliance production, these machines have demonstrated unparalleled versatility and precision, enabling the efficient creation of complex metal profiles and components. The significance of roll forming machines lies in their ability to consistently produce high-quality parts with exceptional dimensional accuracy, meeting the stringent requirements of various applications.

Moreover, the impact of roll forming machines extends beyond traditional manufacturing sectors, with emerging industries recognizing the value of this technology in achieving innovative designs and sustainable solutions. As a result, roll forming machines have become synonymous with reliability, efficiency, and adaptability, driving advancements in product development and enhancing overall manufacturing capabilities.

Looking Ahead: The Continued Evolution of Roll Forming Technology

The future trajectory of roll forming technology is poised for further evolution and innovation. With ongoing research and development efforts, manufacturers are exploring advanced materials, smart technologies, and sustainable practices to enhance the capabilities of roll forming machines. This continuous evolution aims to address evolving market demands for customized solutions while promoting environmental responsibility and resource efficiency.

Furthermore, as industries embrace digital transformation and automation, roll forming machines are expected to integrate seamlessly into smart manufacturing environments. Real-time data monitoring, predictive maintenance systems, and adaptive control mechanisms will redefine the operational landscape of roll forming processes, ensuring enhanced productivity and quality control.

In essence, the continued evolution of roll forming technology will not only shape industrial landscapes but also pave the way for groundbreaking innovations that cater to diverse industry needs while aligning with global sustainability initiatives.

Spanish

Spanish