Simple Metal Coil Slitting Line Wholesale: High Precision Rolling Stainless Steel Coil Strip Slitting Machines

Overview of High Precision Metal Coil Slitting Technology

In metal-making factories, working fast and getting things right is super important. Whether you’re building car parts, making beams for buildings, or cutting custom strips, good tools make a big difference. A metal coil slitting line is a strong machine that turns wide metal coils into narrow strips for other uses. If you want metal coil slitting line wholesale options that are super accurate, this guide is for you. It covers everything about high precision rolling metal stainless steel coil strip slitting line machines, from how they work to why buying in bulk is smart, so you can pick the best for your business.

How Metal Slitting Line Machine Works

A metal slitting line machine is a system that cuts big metal coils—like carbon steel, stainless steel, aluminum, or galvanized sheets—into smaller strips called “mults.” These machines are key for making lots of metal fast with little waste. Big metal processors, like steel mills, say a good slitter can handle metal from 0.1 mm to 16 mm thick and up to 2,100 mm wide. It can run at speeds over 200 m/min. For folks looking at metal coil slitting line wholesale, these machines are great because they fit into existing setups, save time, and make money back fast.

What makes a high precision rolling metal stainless steel coil strip slitting line special? It’s the mix of tough design and smart controls. Basic slitters work for simple jobs, but precision ones are made for stainless steel’s tough traits, like resisting rust and bending. They give smooth edges, super tight measurements (±0.05 mm width accuracy), and clean surfaces. These machines are a must for industries like aerospace or medical tools, where even tiny mistakes can ruin parts.

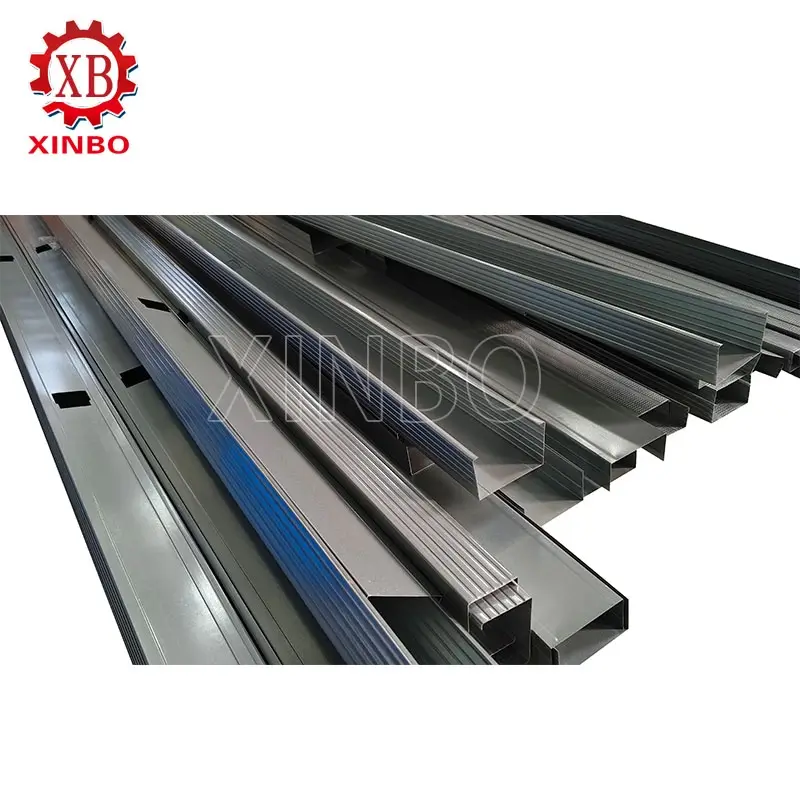

The Essential Components of a Metal Coil Slitting Line

Knowing how a metal slitting line machine is built helps you see why it’s so good. A full system has several parts that work together. Let’s break it down:

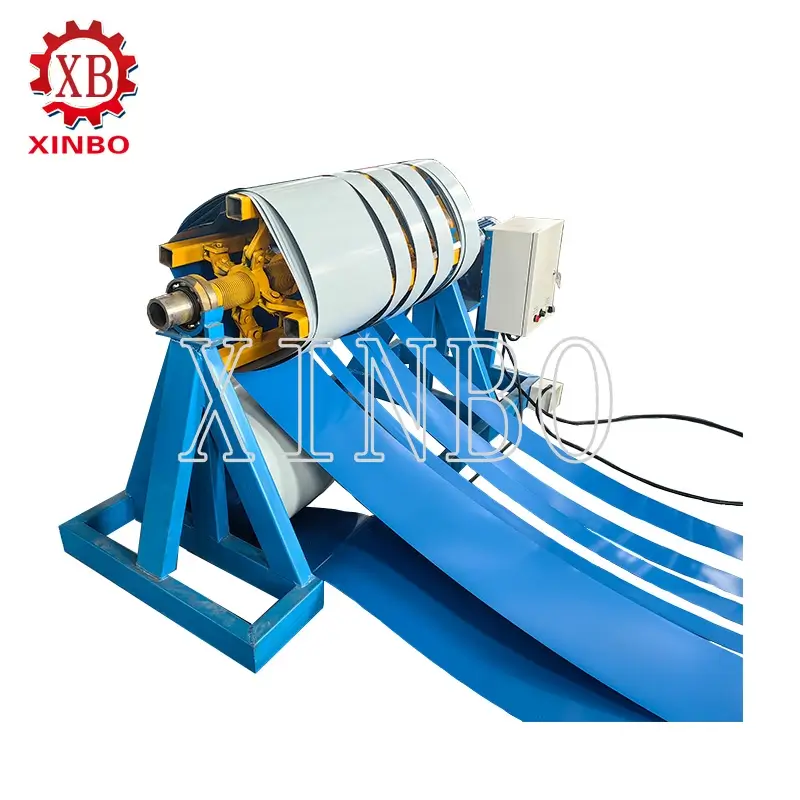

1. Uncoiler and Coil Loading

The process starts with the uncoiler. It’s a hydraulic or mandrel tool that holds the inside of a big coil (up to 30 tons and 2,000 mm OD). It feeds the metal smoothly into the line. Fancy models have auto coil cars for quick loading, cutting downtime. Keeping the right tension is key—too loose, and the strip moves around; too tight, and it stretches. Precision uncoilers use servo motors for steady feeding, especially important for high precision rolling metal stainless steel coil strip slitting line setups where stainless steel’s springy nature needs tight control.

2. Entry Leveler and Pinch Rolls

Before cutting, the metal goes through a leveler, usually with 5 or 7 rolls. This flattens any bumps from the mill. Pinch rolls grab the metal and move it forward without slipping. For stainless steel, these parts are coated or cooled to avoid scratches, keeping the shiny finish.

3. The Slitter Head: Heart of Precision Cutting

This is where the action happens. The slitter head has top and bottom arbors with round knives that cut the strip lengthwise. Top-notch metal coil slitting line systems use shimless or quick-change tools, so you can switch setups in under 5 minutes. Knives, made from high-speed tool steel or carbide, cut 20-30% into the metal for clean edges, with burrs under 0.02 mm. For high precision rolling metal stainless steel coil strip slitting line, double eccentric heads cut down shakes, allowing up to 40 cuts per pass on 1 mm thick metal.

4. Looping Pit and Tension Control

A looping pit handles speed differences between the slitter and recoiler. This stops bending or stacking issues in the strips. Tension stations, using bridles, pads, or belts, pull evenly (up to 50 kN). This is key for tight, clean coils. In stainless steel jobs, adjustable air systems fine-tune tension to avoid scratches on smooth surfaces.

5. Recoiler and Scrap Handling

The recoiler winds strips onto mandrels that expand to hold tight. Dual or turret designs let you keep working by switching coils. Scrap from edge cuts gets wound on winders or chopped into balls. Modern lines recycle up to 95% of it.

Together, these parts make a super efficient system. A single metal slitting line machine can handle 500-1,000 tons per shift, cutting material costs by 15-20% with less waste.

Why Choose High Precision for Stainless Steel Coil Processing?

Stainless steel is tricky—it’s tough against rust (like grades 304 or 316) but hard to cut. It can harden, crack at edges, or stick to blades. A high precision rolling metal stainless steel coil strip slitting line handles these with special features:

-

Cool Tools: Razor or crush-cut blades with non-stick coatings tackle stainless steel’s toughness. They keep edges square, better than 0.010 inches per foot.

-

Cooling and Oil: Mist systems stop heat buildup, keeping strips strong during fast runs (up to 300 fpm).

-

Quality Checks: Laser gauges watch width and thickness in real-time, fixing any issues automatically.

The result? Later steps like stamping or roll forming work better—up to 98% success in precision setups. This saves millions yearly for big users.

Wholesale Advantages: Scaling Up with Metal Coil Slitting Line Wholesale

For metal shops or factories, metal coil slitting line wholesale is a smart move, not just a buy. Getting machines in bulk from trusted makers like XINBO brings:

-

Cheaper Prices: Wholesale cuts costs by 20-30% per machine. You get bigger discounts for multiple lines (like 3+).

-

Custom Fits: Pick specs like gauge range (0.2-3 mm for light jobs) or automation (PLC or full Industry 4.0).

-

Quick Setup: Pre-built parts ship in 40ft containers and are ready in 4-6 weeks.

For example, a medium-sized metal shop switched to a wholesale metal slitting line fleet. It boosted output by 40%, letting them deliver just-in-time to car makers.

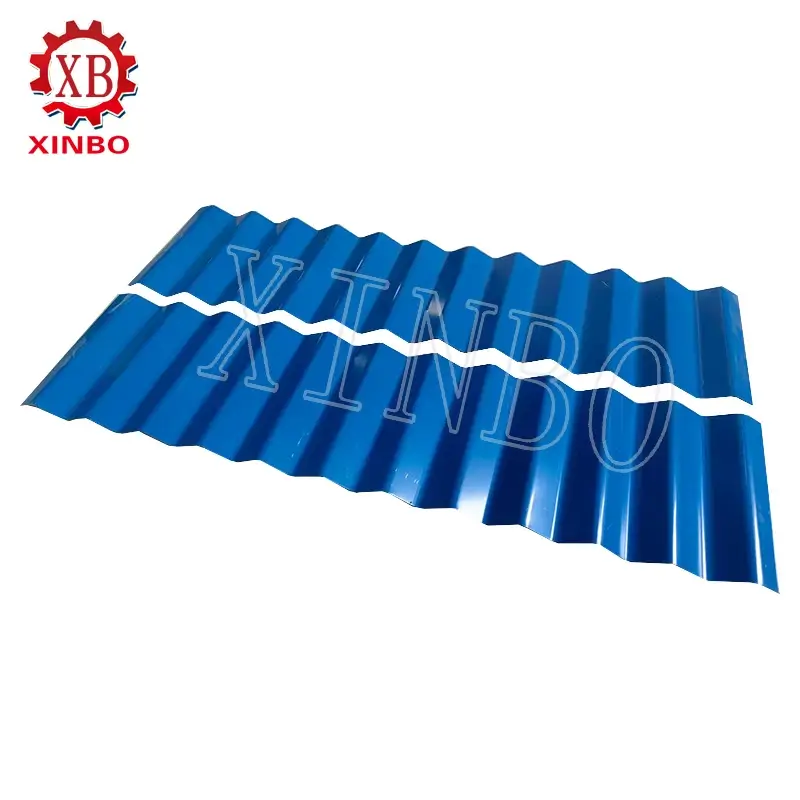

Applications Across Industries

These machines work in many fields:

-

Cars: Cutting stainless coils for exhaust pipes or door panels with ±0.1 mm accuracy for perfect fit.

-

Building: Narrow strips for roofs or walls, cut at 150 m/min for big batches.

-

Appliances: Precise cuts for washer drums, saving waste on painted coils.

-

Electronics: Super-thin stainless for battery foils, down to 0.05 mm thick.

In each, a high precision rolling metal stainless steel coil strip slitting line gives the reliability needed to stay ahead.

Maintenance and Optimization Tips

To keep your machine running 20+ years, try these tips:

-

Daily Checks: Look at blades for wear. Sharpen every 500 hours.

-

Oil Up: Use food-safe oils for stainless steel to avoid stains.

-

Software Updates: Use IoT tools for early fixes, cutting downtime by 50%.

-

Train Workers: Teach tension settings—bad ones cause 70% of edge problems.

Regular checks keep machines lasting and precise.

Partnering with XINBO for Wholesale Excellence

When picking metal coil slitting line wholesale, know-how matters. XINBO, a leader in metal shaping since 2014, makes cold rolling and slitting machines for markets like Europe and North America. Their high precision rolling metal stainless steel coil strip slitting line is top-notch: modular designs fit standard containers for easy shipping, and custom builds match your workflow.

XINBO’s quality, backed by ISO certifications and a strong R&D team, means tough, accurate machines. From first talks to full setup, they make ODM simple and hassle-free.Ask for a free quote now—let’s work together!

FAQ

What is a metal coil slitting line, and how does it differ from a standard cutting machine?

It’s a special system for cutting wide coils into narrow strips, great for big production. Unlike regular cutters, it uses round knives for smooth edges and includes unwinding, flattening, and rewinding for full efficiency.

Can a high precision rolling metal stainless steel coil strip slitting line handle other metals besides stainless steel?

Yes, it works with carbon steel, aluminum, galvanized sheets, copper, and more. XINBO customizes for different metals, setting the right tension and tools.

What are the typical speed and capacity ranges for a metal slitting line machine?

Speeds hit 200-400 m/min, handling 5-40 tons per coil and thicknesses 0.1-16 mm. XINBO’s wholesale models fit your needs.

How do I maintain edge quality in stainless steel slitting?

Use cooled blades, exact tension, and real-time checks. XINBO’s designs keep burrs under 0.02 mm.

What wholesale benefits does XINBO offer for metal coil slitting line purchases?

XINBO gives bulk discounts, container shipping, and full customization, with fast delivery for global buyers.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia