Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

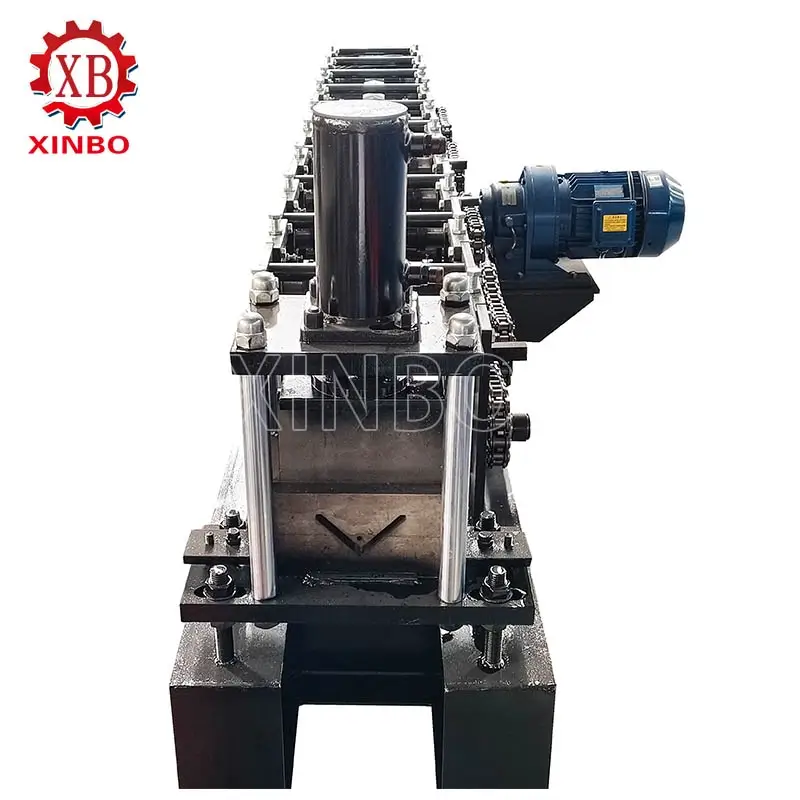

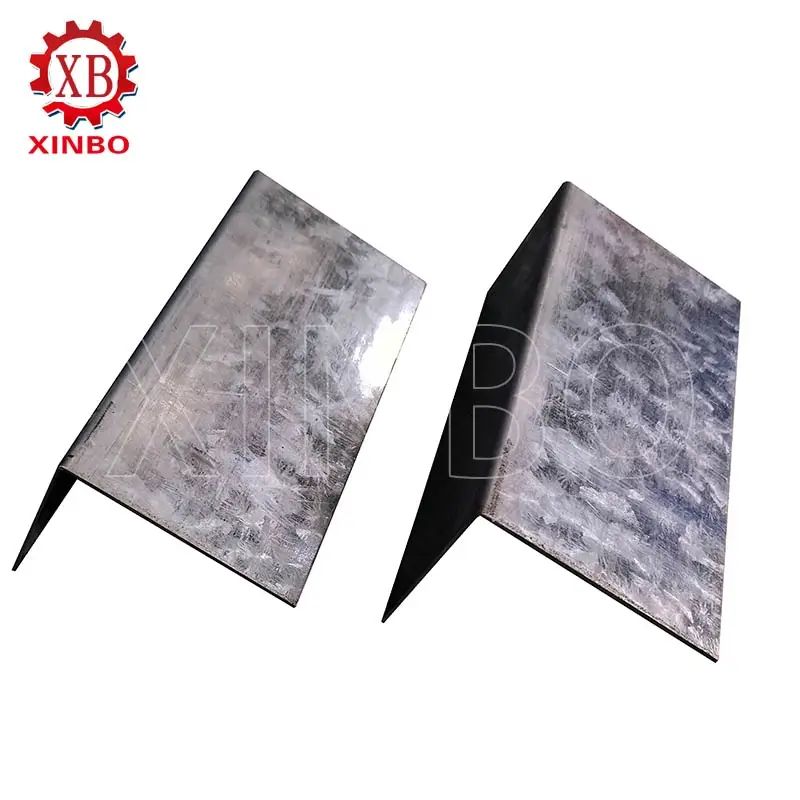

VIEW MORE→Wall angle roll forming machines are special tools. They make vertical wall angles for garage door systems. These parts are key. They attach to garage walls. They support horizontal door tracks. They ensure smooth door panel movement. These machines are often part of a garage door production line. They work with materials like cold-rolled steel or galvanized steel. These have thicknesses from 0.3 mm to 2.0 mm.

Wall angle roll forming machines are bending systems. They shape metal sheets, strips, or coils into specific shapes. They use a series of rollers. In garage door making, they form vertical wall angles. These are usually C or U-shaped with flanges. The flanges attach to garage walls. These angles support horizontal tracks. They ensure smooth sectional garage door movement.

Their job goes beyond shaping metal. They improve garage door function and toughness. They ensure accuracy and steady quality in production. They handle materials like galvanized steel and cold-rolled steel. This makes them flexible and vital in big manufacturing setups.

Wall angle roll forming machines often use cold-rolled or galvanized steel. Thicknesses range from 0.3 mm to 2.0 mm. This range meets different strength needs. It keeps parts strong.

These machines are fast. They can reach speeds up to 60 m/min. Advanced systems hit about 100 ft/min (30.5 m/min). This speed meets high production needs quickly.

Key parts include:

The machines need a three-phase power supply. This can be 220V, 380V, 415V, or 460V at 50/60Hz. They have PLC control systems. These include touchscreen displays. They make operation easy and accurate.

Optional extras include pre-cutting tools and safety covers. Quick-change bases allow multi-shape production. Film application tools add flexibility.

|

Parameter |

Specification |

|

Material Type |

Cold-rolled steel, Galvanized steel |

|

Material Thickness |

0.3 mm – 2.0 mm |

|

Production Speed |

Up to 60 m/min (Advanced: ~100 ft/min) |

|

Decoiler Capacity |

5–15 tons |

|

Roller Stations |

Up to 41 |

|

Power Supply |

Three-phase (220V/380V/415V/460V), 50/60Hz |

Wall angle roll forming machines follow several steps:

A decoiler unwinds metal coils. These are often galvanized steel. It feeds them smoothly into the machine. Decoilers have an inner diameter of 480–508 mm. Their outer diameter can reach 1000 mm.

The metal sheet moves through roller stations. These shape it step by step into profiles like C or U shapes. Rollers are made from heat-treated 45# steel. They have hardness of HRC58-62°. This ensures long-lasting use.

Formed profiles may get punched or notched. These steps happen in the production line. They allow for fastener placement or assembly fit.

Profiles are cut to set lengths. Hydraulic post-cutting or flying cutting systems are used. Automated stacking systems organize finished products neatly.

A PLC system watches every step. It ensures accuracy and steady quality. Usually, only one or two workers manage the whole process. This is due to automation.

Wall angle roll forming machines are vital. They make key parts for sectional garage doors. They combine speed, accuracy, and flexibility in design and function.

Wall angle roll forming machines are crucial in garage door making. They create vertical wall angles. These attach to garage walls. They support horizontal door tracks. This ensures smooth sectional garage door movement. The parts they make are key for vertical lift and roll-up doors. They add stability and toughness.

Wall angles are important in insulated garage doors too. They work with insulation injection systems. These machines handle materials like cold-rolled or galvanized steel. Thicknesses range from 0.3 mm to 2.0 mm. This makes them flexible for many uses. Their role in big production lines shows their value. They meet the garage door industry’s high demands.

Wall angle roll forming machines offer many customization options. They meet varied design needs in the garage door industry. They can make profiles like C or U-shaped wall angles. These often have flanges for attachment. Clients provide drawings or samples. This lets makers tailor the equipment to specific needs.

These machines are used in industrial and commercial fields. They make parts for vertical lift doors, roll-up doors, and insulated doors. For example, sectional garage doors need wall angles. These fit smoothly with tracks and panels. The ability to make multi-profile designs adds to their use. They suit complex projects.

Optional features boost flexibility. These include pre-cutting tools and quick-change bases for multi-profile production. Automated stacking systems help too. Certifications like CE ensure global quality standards. Patented tech improves performance.

The garage door industry has grown a lot. Wall angle roll forming machines play a big role. They drive efficiency and new ideas. These machines have been used for over 14 years. This shows their steady presence and dependability.

Automation is a major trend. Features like fully automated stacking and quick tool changes are common. They boost production speed. Demand for custom solutions is growing. Clients want tailored designs that standard machines can’t fully provide.

Sustainability is another focus. Machines that process recyclable materials like galvanized steel support green practices. As market needs change, makers keep improving. They add advanced control systems like PLCs and touchscreen displays. These ensure accuracy and ease of use.

XinBo is a trusted maker since 2014. It focuses on quality and new tech. XinBo designs its roll forming machines to meet customer needs. Its equipment meets Euro standards like CE certification. It offers custom solutions through ODM and OEM services.

XinBo’s skills cover many metal roll forming uses. These include roof sheets, roller shutter doors, door frames, and more. Its design team tailors each machine to client needs. They also optimize shipping costs. Equipment fits standard containers.

XinBo exports to Europe, the Middle East, Africa, America, South America, and beyond. Its products are known for smart design and fair structure. The company offers full services. These range from product design to after-sales support. Its principles are dedication, innovation, mutual benefit, and unity.

Choose XinBo’s wall angle roll forming machine for garage door needs. You get dependable equipment. It comes with great customer service.

These machines often process cold-rolled steel or galvanized steel. Thicknesses range from 0.3 mm to 2.0 mm.

Speeds can reach up to 60 m/min. Advanced setups hit about 100 ft/min (30.5 m/min).

Yes, they are very customizable. Makers adjust specs like profile sizes. Optional features include pre-cutting tools or automated stacking systems.

Wall angles provide support. They work with insulation injection systems. This improves heat efficiency.

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→