Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

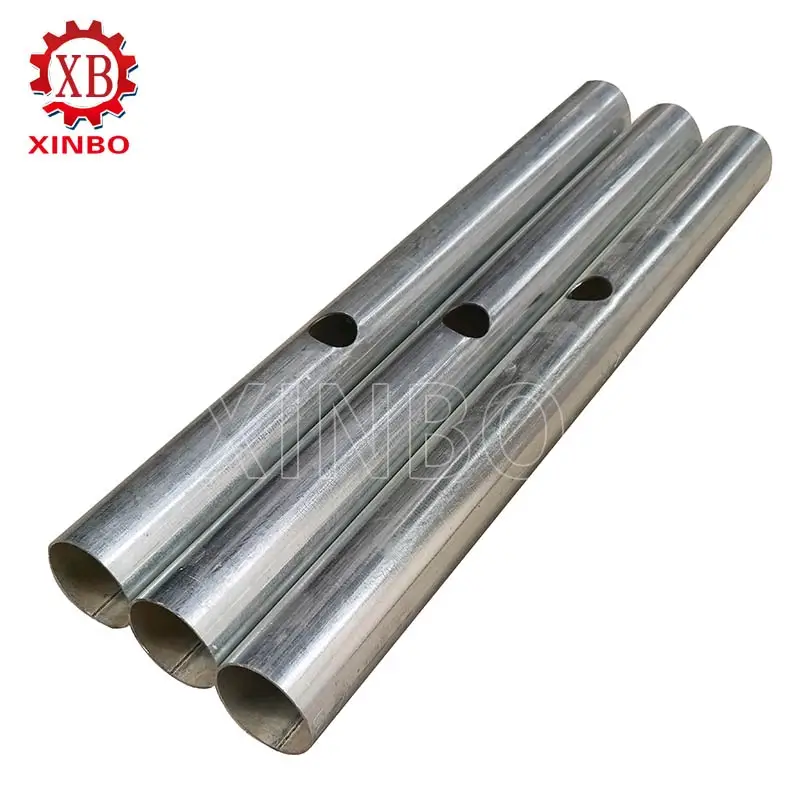

VIEW MORE→Welded steel pipes are made by rolling a metal sheet into a round shape. Then, the edges are welded together. These pipes are known for their strong structure, flexibility, and low cost. They have even wall thickness, smooth inside surfaces, and great strength. This makes them perfect for many uses. The welded roll-formed pipe is sturdy. It also helps save steel and reduces building work.

Welded steel pipes are often used in furniture making. They are light but tough. These pipes form the base for chairs, tables, bed frames, and other furniture pieces.

In the oil and gas industry, these pipes move crude oil, natural gas, and refined products over long distances. They work well because they can handle high pressure. This makes them vital for this field.

Car industries use welded steel pipes for fuel lines, exhaust systems, and structural parts. Their resistance to rust and strong weight-to-strength ratio improve vehicle performance and lifespan.

A Welded Pipe Roll Forming Machine is a special tool designed to make steel pipes in a continuous process. It rolls metal sheets into round shapes. Then, it welds the edges to create pipes. This machine is key for industries needing top-quality pipes with exact sizes.

The decoiler unit holds the raw material coil. It feeds the material into the machine. This ensures smooth unrolling during production.

This part shapes the flat metal sheet into a round form. It uses multiple rollers. These rollers are carefully designed to keep pipe sizes consistent.

The welding section joins the edges of the rolled sheet. It uses methods like high-frequency welding or TIG welding. Gas Tungsten Arc Welding (GTAW) or TIG Welding is a joining process used on stainless steel.

After shaping and welding, the cutting mechanism trims the pipe to set lengths. It uses hydraulic or servo-driven cutting systems.

Production starts with cutting wide steel coils into narrow strips. These strips are suitable for pipe shaping. This step ensures accurate width alignment for smooth production.

The decoiler unrolls the cut steel strips onto a feeding platform. Proper tension control prevents material damage during this stage.

The roll forming system slowly bends the flat strip into a round shape. It uses multiple roller stations. The Welded Pipe Roll Forming Machine is special equipment for continuous rolling and cold-forming on steel sheets.

High-frequency welding uses electric currents to heat and join metal edges. It does not need extra filler materials. This method is great for making strong seams quickly.

During welding, the edges are aligned precisely. This ensures even seam quality. An arc welding process or TIG welding for stainless steel heats the metal. Argon gas protects the weld area from air contaminants.

After welding, sizing rollers adjust the pipe’s diameter to meet exact standards. This step ensures all pipes are consistent.

Finally, servo-driven cutting systems slice the pipes into needed lengths. They create minimal waste. Servo tracking cutting saws are used for accurate cutting.

For businesses looking for advanced solutions in welded pipe production, Xinbo Welded Pipe Roll Forming Machine offers custom designs. These meet specific needs. With modern CNC machining and efficient production, Xinbo ensures top-quality results at fair prices. Contact us today to explore our innovative machines!

Gas Tungsten Arc Welding (GTAW) or TIG Welding is a joining process for stainless steel. It uses a tungsten electrode to heat the metal. Argon gas shields the weld area from air contaminants. This ensures accuracy and strength. It is perfect for uses needing high-quality welds. The GTAW process is often used in advanced Welded Pipe Roll Forming Machines. It ensures smooth and strong pipe joints.

Round Tube TIG welding lines with plasma cutting support thicknesses up to 3.0mm. They handle tube diameters up to φ160mm. These features make them flexible for various industrial needs. They work for furniture making and oil pipelines. The machines handle different tube sizes well without lowering quality.

Modern welding machines use plasma cutting for clean and precise cuts. Servo tracking cutting saws ensure accurate cuts. They reduce material waste and meet exact length needs. This feature boosts productivity and lowers costs.

The hydraulic decoiler starts the production line. It has a 7-ton loading capacity. The steel coil’s inner diameter ranges from φ480-φ508mm. Its outer diameter reaches up to φ1800mm. This part ensures smooth unrolling of raw materials. It keeps steady tension to avoid material damage.

The leveling unit prepares the raw material by flattening it. This happens before it moves to other processes. It has seven rollers made from Gr15 material. The unit works at speeds of 1-15m/min. Its accurate alignment ensures even material thickness. This is vital for top-quality pipe production.

The hydraulic punch station makes holes or slots in the material. This is based on specific designs. It includes two sets of punch dies made from Gr12MoV material. These ensure toughness and accuracy in punching.

The Welded Pipe Roll Forming Machine shapes the flattened sheet into round pipes. It uses multiple roller stations. The machine has 17 roller groups made from GCr15 material with heat treatment (HRC58-62°). Nodular iron casting pillars support the rollers. This provides stability and accuracy during operation.

The servo tracking cutting saw ensures precise cutting of pipes. It is powered by a Delta servo motor. This mechanism offers cutting accuracy within ±1.0mm. It reduces waste and improves efficiency in the production line.

The output table collects finished pipes. It ensures smooth handling and storage. It is designed to handle various pipe sizes. It also keeps their structure intact during transfer.

The hydraulic feeding table supports efficient loading of steel coils into the decoiler. Its strong design works with heavy-duty tasks. It reduces manual work and improves workflow speed.

The leveling unit’s rollers are made from high-strength Gr15 material. This ensures long life and dependability during continuous use. Its adjustable speed settings allow customization for different material types and thicknesses.

This unit has two punch dies made from Gr12MoV material. It delivers accurate punching for various industrial uses. Its hydraulic system ensures steady performance even under heavy workloads.

The roll forming machine’s frame is made from 10mm welded plates. It undergoes stress-relieving treatments. This strong design reduces vibrations during operation. It improves product quality and machine lifespan.

The hydraulic pump station has an 11KW motor. It uses fan wind cooling. This provides dependable performance for all hydraulic parts in the production line.

The servo tracking cutting saw ensures high accuracy. It keeps cutting tolerances within ±1.0mm. This precision reduces waste and ensures consistent pipe lengths.

The electrical control cabinet uses advanced parts like PLCs, frequency inverters, and touch screens (all Delta brand). These allow automated control of machine functions. They ensure accuracy and easy operation.

Cutting length tolerances stay within ±1.0mm. Vertical and horizontal tolerances are kept within ±1.5mm. These strict standards ensure all pipes are consistent.

For industries seeking new solutions in pipe manufacturing, Xinbo Welded Pipe Roll Forming Machine offers modern equipment. It is tailored to specific needs. With a focus on customization, fair pricing, and efficient workflows, Xinbo is a dependable partner. Reach out today to explore our wide range of solutions!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→