How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

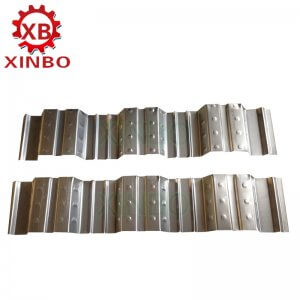

decking floor roll forming machine

The Floor Deck Roll Forming Machine is a type of machinery that is specifically designed to produce floor decking panels or sheets. This machine is highly efficient and can produce high-quality deck sheets in a short amount of time.

The Floor Deck Roll Forming Machine is made up of several components, including a decoiler, a feeding unit, a roll forming unit, a hydraulic cutting unit, a control system, and a product output table. These components work together to ensure that the machine operates smoothly and produces high-quality products.

|

ITEM |

SPECIFICATION |

|

Processing Material |

GI |

|

Input Width(mm) |

1000 |

|

Formed Width(mm) |

688 |

|

Processing Thickness(mm) |

0.8—1.0 |

|

Material of Rollers |

45# steel,with hard chrome coated |

|

Diameter of Shaft |

Ф80mm |

|

Production Speed |

8—10m/min |

|

Roller Driven |

Decelerating Motor+Chain Transmission |

|

Cutting Model |

Hydraulic Profile Cutting |

|

Length Measurement |

Encoder |

|

Control Style |

PLC |

|

Operation Model |

Button + Touch Screen |

|

Total Power |

11+11+5.5KW |

|

Voltage |

380V 50HZ or at buyer’s request |

|

Number of roller stations |

26 or as designing |