How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

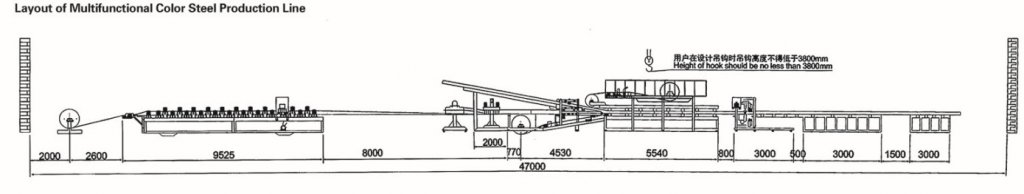

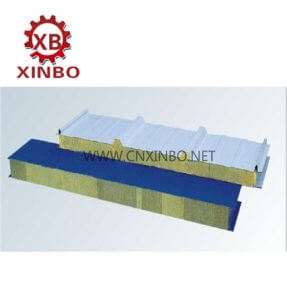

This production line adopts superior technology by pneumatic,electricity,and mechanism,which is the specialized machine for producing color steel sandwich panel.The production speed can be adjusted by stepless speed regulation.The complete line includes uncoiling machine,forming machine,compositing machine(ribs forming,rubber coating,warming up.compositing,hemming,notching,edge processing,pneumatic auto cutting),It’s necessary for making wall and roof panel of workshop,storage and so on.

|

Overall power equipment: |

25kw |

|

Size of the line: |

overall length of the line is about 26000 mm |

|

Voltage |

380V,50Hz or as customer need |

|

Produced panel thickness |

50-200mm |

|

Overall width of the line: |

2200mm(max) |

|

Overall height of the line: |

2100mm |

|

Overall weight of the line: |

~ 10 t |

Main Parts of the EPS Sandwich Panel Line:

Roof forming machine

a:Into shearing device

b:Forming machine itself

c:Panelmachine

Leveler for thickness

Compositerubber rollers

b. Gluesection

Glue pumps

Spreaduniformlydevice

c. Groovingdevice

e. Intoshearing

Machinery Parts:

|

Type of Shearing: |

Electrical Shearing |

|

Driven Power: |

0.75 kw |

|

b. Forming Machine Itself |

|

|

Design of profile: |

Same as sample |

|

Type of forming: |

roll forming |

|

Shaft diameter: |

70mm |

|

Material of roller: |

45 steel heat treatment |

|

Thickness of chromic plating of roller surface: |

0.05~0.06mm |

|

Speed of forming: |

5~6.0m/min synchronies with panel machine |

|

Type of synchronies: |

electrical synchronies |

|

Driven power: |

3.0 kw |

|

Size of forming machine: |

5000×1650×2000mm |

2.Panel machine

|

i. Composite rubber rollers |

|

|

roller diameter: |

150 mm |

|

thickness of composite rubber layer: |

10mm |

|

hardness of composite rubber layer: |

60 |

|

Numbers of rollers |

as designing |

|

numbers of pump: |

2 sets |

|

Driven power: |

0.37 Kw*2 |

|

Flow volume of glue: |

0~0.4 kg per pump |

|

type of flow volume control: |

Change frequency (Black) 1.5 |

|

Scale of glue: (white): |

|

speed of spreading: |

80 times/min |

|

driven power: |

0.5kw ×3 |

|

Type of apply guard film: |

Automatic |

|

type of shearing: |

Electrical |

|

numbers of shear: |

1 set |

|

Driven power: |

0.75KW |

|

Electrical Voltage: |

380V/3Ph/50Hz or as customer need |

|

Type of controlling: |

PLC |

|

Touch screen: |

1 set |

|

Speed measure device: |

1 set |

|

Parts of electrical control system: |

1 set |

This producing line is maintained for its whole life. For the first 18 months, we will replace broken parts free of charge. During the coming period, we will sell you spare parts at factory price. When the machine is used at abroad, we will send the professional technician to debug. Buyers should take all the fees for technicians travelling abroad.