How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

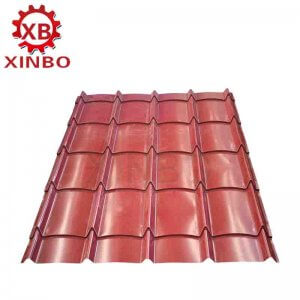

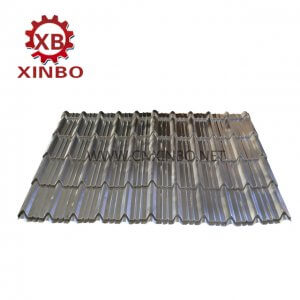

Glazed Tile Roll Forming Machine

Glazed tile forming machine | 840 roof panel roll forming machine | metal roof panel roll forming machine | metal roof panel roll forming machine | trapezoidal roof panel roll forming machine | roof panel roll forming machine | wall panel roll forming machine. Our veneer forming machines sell well in many countries, professional and experienced engineers design to ensure the efficiency and safety of the machine, we can customize the machine according to requirements,Here are the pictures for your reference.

|

Item |

Specification |

|

Processing Material |

PPGI,GI,Aluminium |

|

Material of Rollers |

45# steel,with heat treatment |

|

Diameter of Shaft |

Ф70mm |

|

Roller Driven |

Decelerating Motor+Chain Transmission |

|

Cutting Model |

Hydraulic Profile Cutting |

|

Length Measurement |

Encoder |

|

control method |

PLC control system(imported Brand) |

|

Total Power |

3+3KW |

|

Voltage |

380V 50HZ or at buyer’s request |