How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

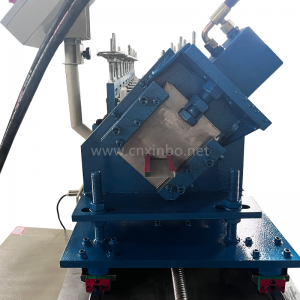

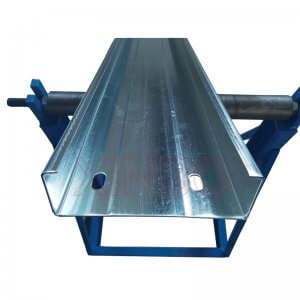

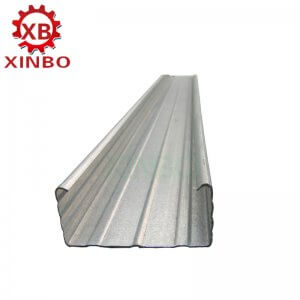

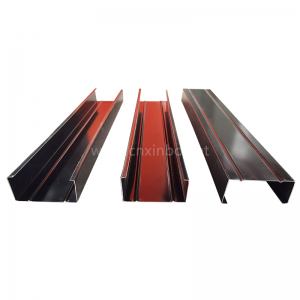

light keel stud and track machine

Light keel roll forming machines are an essential part of the construction industry. They are used to create lightweight, strong, and durable metal frames that are used in ceiling systems, partition walls, and other construction projects. These machines use a process called roll forming to shape metal into the desired shape and size.

The process of roll forming involves feeding a strip of metal through a series of rollers that gradually bend and shape the metal into the desired shape. The metal is then cut to the desired length and can be used in construction projects. Light keel roll forming machines are designed to handle a variety of metals, including steel, aluminum, and copper.

|

No. |

Item |

Specification |

|

1. |

Processing Material |

GI.Black steel.Al |

|

2. |

Input Width(mm) |

As designing |

|

3. |

Formed Width(mm) |

As customer drawings |

|

4. |

Processing Thickness(mm) |

0.8-1.2mm |

|

5. |

Material of Rollers |

45# steel,with hard chrome coated |

|

6. |

Diameter of Shaft |

Ф70-80mm |

|

7. |

No.of rollers |

13 |

|

8. |

Production Speed |

0-15m/min |

|

9. |

Roller Driven |

Decelerating Motor+gear+Chain Transmission |

|

10. |

Cutting Model |

Hydraulic Profile Cutting |

|

11. |

Length Measurement |

Encoder |

|

12. |

Control Style |

PLC |

|

13. |

Operation Model |

Button+ screen |

|

14. |

Total Power |

5.5KW |

|

14. |

Voltage |

380V 50HZ or at buyer’s request |