Efficient and Versatile: Light Steel Keel Forming Machine

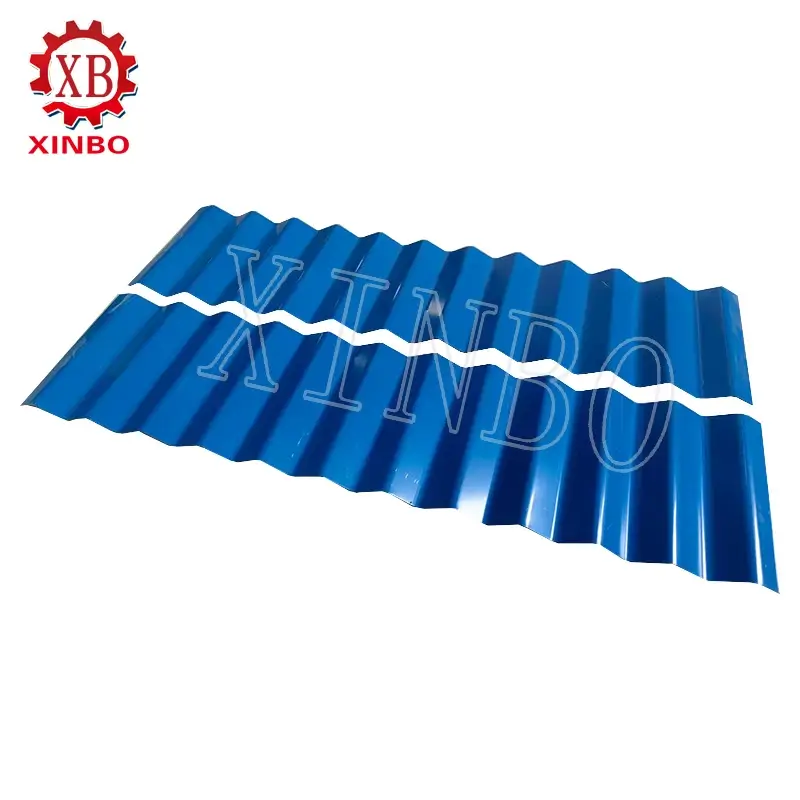

The light steel keel forming machine is a real standout. Also known as the light steel keel roll forming machine, this cool tool is built to turn galvanized steel coils into strong, light structural pieces with awesome speed. Whether you’re making C-shaped studs for room dividers or U-profiles for hanging ceilings, this machine gives steady results that match tough industry rules.

If you’re looking for tips on picking the best light steel keel roll forming machine or boosting light steel keel production line speed, you’re in the right spot.

What is the Light Steel Keel Forming Machine

At its heart, the light steel keel forming machine is a special tool for shaping thin galvanized steel strips—usually 0.4mm to 1.2mm thick—into exact keel shapes. These shapes are the backbone for non-weight-bearing structures in homes, offices, and factories. Unlike old heavy steel methods, this machine uses a steady cold-rolling process. It avoids heat warping, so the steel keeps its galvanized coating for great rust protection.

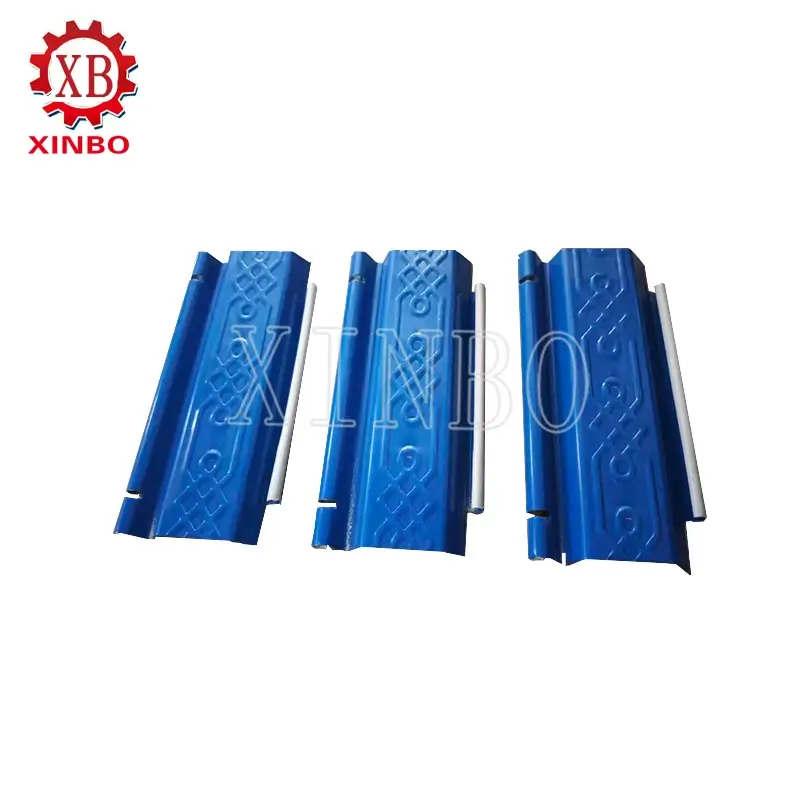

This machine is super flexible. It can make different shapes, like C, U, L, and omega channels, all tweaked with programmable controls. This makes it perfect for special orders, like custom light steel keel profiles for modular homes or standard tracks for office setups. Its speed comes from auto-feeding systems that uncoil steel strips at 30-50 meters per minute, depending on the model.

From a science view, the light steel keel roll forming machine is great at keeping steel’s strength. The cold-forming process makes the material stronger through work-hardening. This creates keels with a tensile strength of 300-550 MPa. These keels are 2-3 times lighter than wooden frames, making them ideal for earthquake-prone areas where flexibility and toughness matter.

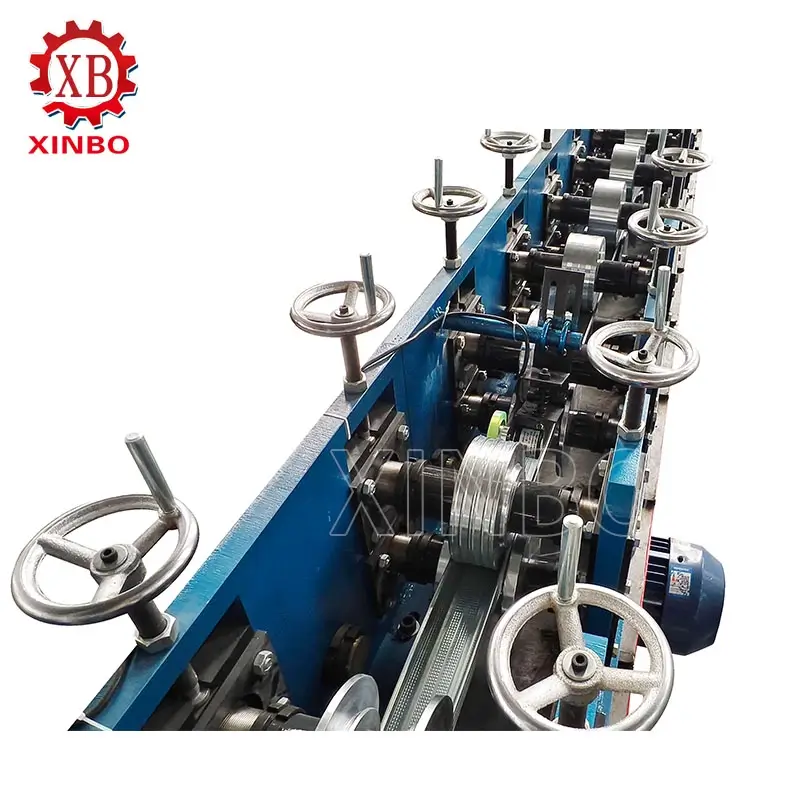

Core Components of the Light Steel Keel Machine

Let’s dig into the key parts that make the light steel keel forming machine a champ at precise work.

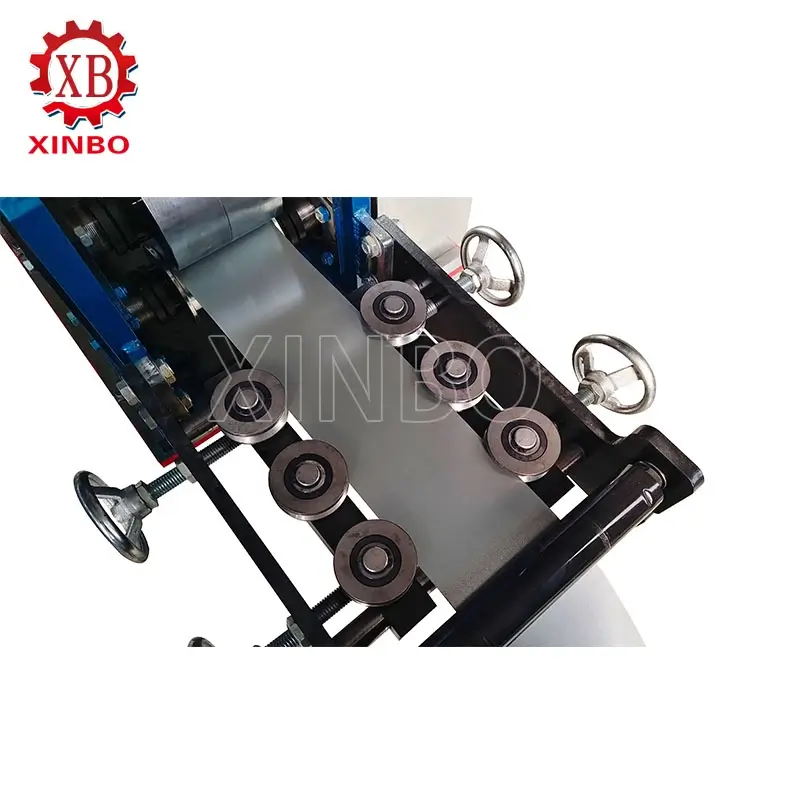

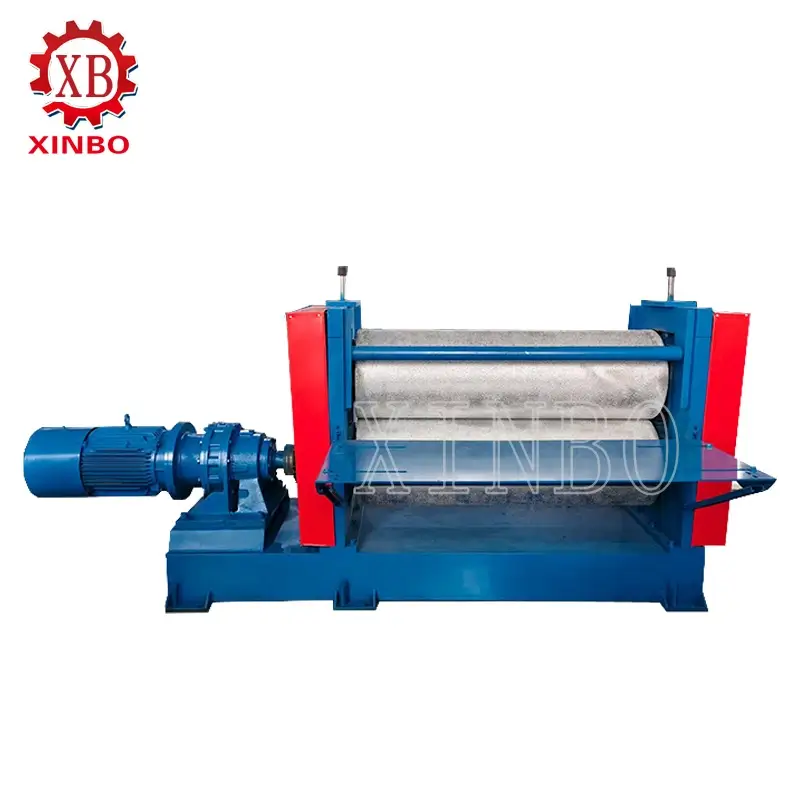

Decoiler and Feeding System

It all starts with the decoiler, a sturdy unit that holds coils weighing 3-5 tons and up to 1,200mm wide. It feeds the steel smoothly without tension, preventing slips that could cause flaws. Paired with leveling rollers, this system straightens the steel, fixing any coil bends for perfect forming later.

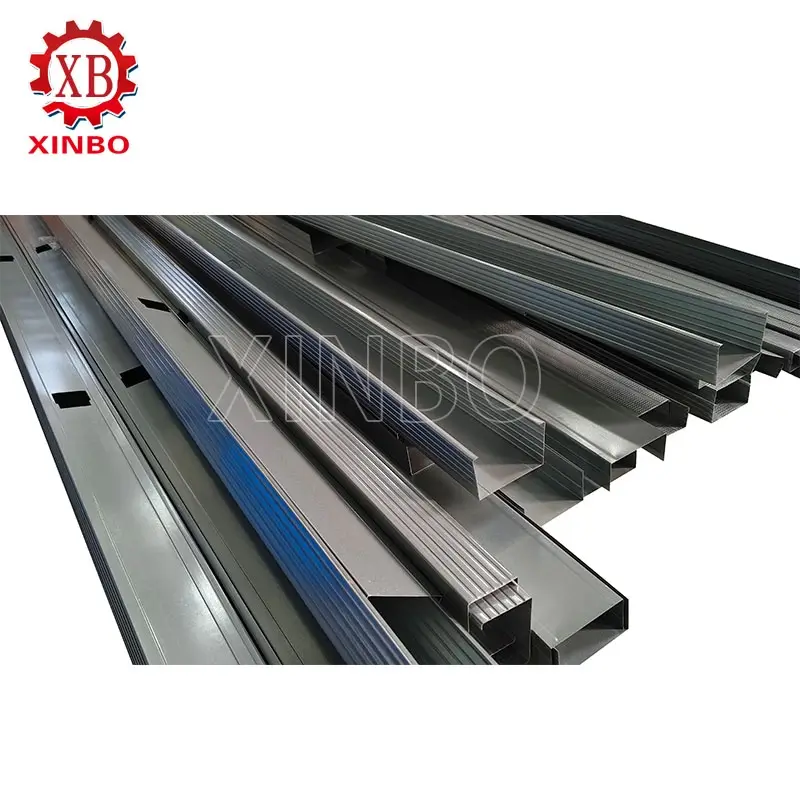

Roll Forming Stations

The core of the machine is its 15-20 forming stations. Each has hardened chrome-plated rollers made to super tight specs (±0.05mm). These stations slowly bend the strip through small angles, creating complex shapes without cracking. For a standard 50mm x 50mm C-keel, the rollers work together to shape the web, flanges, and lips in one go, keeping spring-back low.

Hydraulic Cutting and Stacking Mechanism

Once shaped, the profile moves to the flying shear or hydraulic guillotine. It cuts to lengths of 2-6 meters with a ±1mm accuracy. Servo-driven controls keep production going without stops. The stacking unit then neatly organizes profiles for bundling and shipping, making the workflow super smooth.

Technical Specifications for Optimal Performance

When choosing a light steel keel roll forming machine, specs are key to matching your needs. Standard models have a main motor power of 7.5-15 kW, with line speeds from 10-60 m/min. They work with 380V/50Hz/3-phase power for global use. The machine’s size—about 8m x 1.5m x 1.2m—fits well in mid-sized factories.

Fancy models include PLC touch-screen controls for live monitoring, with sensors for thickness checks and edge alignment. Safety features like emergency stops and protective covers meet CE standards, keeping workers safe. For high-speed light steel keel production lines, go for models with servo feeders that sync feeding accuracy to 0.1mm, great for just-in-time building.

Operational Principles and Process Excellence

Running a light steel keel machine is like a well-played song of automation and human checks. It starts with loading a galvanized coil onto the decoiler. Hydraulic grips hold it tight. As the strip moves forward, guide pins line it up before it hits the leveling unit. This applies steady pressure to flatten curls.

In the forming section, the strip meets a series of rollers. Entry guides set the path, breakdown rolls start the bend, and fin passes sharpen the edges. This step-by-step shaping, planned with careful design, spreads stress evenly to avoid lip flares or web buckling. Optional mid-line punching can add holes for screws, perfect for light steel keel framing systems in drywall work.

After forming, the profile cools on its own before reaching the cutting station. A hydraulic ram makes clean, burr-free cuts at 10-20 strokes per minute. The whole line is run by a PLC, with stored settings for quick profile switches—under 30 minutes for most changes. This flexibility supports outputs like 38mm mini-studs for home ceilings or 100mm deep channels for office walls.

Step-by-Step Workflow in Action

Picture a typical run making 4,000 meters of 75mm C-keels daily:

-

Coil Prep: Unload and check a 5-ton coil for surface issues.

-

Feeding and Leveling: Move at 40 m/min, leveling to ±0.5mm flatness.

-

Forming: Pass through 18 stations, shaping the profile in 10 seconds per meter.

-

Punching and Cutting: Add 20mm holes and cut to 3m lengths.

-

Quality Check and Stacking: Auto-check sizes, then stack via conveyor.

This smooth process hits goals and keeps defects below 0.5%, way better than hand-done methods.

Applications Across Diverse Construction Scenarios

The light steel keel roll forming machine isn’t stuck in one area—its products power all kinds of building projects, from small fixes to huge skyscrapers. In homes, light steel keels build frames for room dividers. They make it easy to rearrange spaces without load-bearing hassles. Their light weight (just 25-30 kg/m²) speeds up setup, often finishing a room frame in hours, not days.

In office projects, these profiles make ceiling grids for acoustic panels and lights. The precision of light steel keel forming ensures even hangs, key for good looks in stores or offices. In factories, L-profiles support mezzanine floors, offering fire-rated strength (up to 120 minutes) with the right coatings.

Outside, U-channels work with insulated panels for energy-saving building facades. In earthquake zones, the bendy nature of cold-formed steel handles shakes better than stiff options, making it a go-to choice. New trends like off-site building boost its role. Factories using light steel keel production lines assemble whole wall sections, cutting on-site labor by 50% and avoiding weather delays.

Key Advantages: Why Choose a Light Steel Keel Roll Forming Machine

Speed and flexibility make the light steel keel machine shine. It produces 20-50 tons monthly from one line, beating batch methods. Precision—tolerances under 0.2mm—cuts rework, boosting yield to 98%.

Its flexibility covers many shapes. One machine handles 10+ profiles with quick tool swaps, keeping your investment future-ready. Cost savings add up: low waste (under 2%) and energy use (15 kWh/ton) bring payback in 12-18 months. The keels last 50+ years in damp climates, thanks to zinc coatings of 120-275 g/m².

Comparative Edge in Material and Performance

Compared to aluminum extrusions, light steel gives 30% more stiffness at half the cost. Forming machines let you tweak thicknesses for the best strength.

FAQ: Common Queries on Light Steel Keel Forming Machines

What is the typical production speed of a light steel keel roll forming machine?

Most hit 20-50 meters per minute, depending on profile complexity and steel thickness.

Can the light steel keel machine handle custom profiles?

Yes, with adjustable rollers and CNC programming, it makes tailored shapes like L or omega channels for specific jobs.

What materials are best for light steel keel forming?

Galvanized steel coils (0.4-1.2mm thick, 120-275g/m² zinc) ensure rust resistance and easy shaping.

How does the machine help sustainable construction?

With low waste (<2%) and recyclable steel, it cuts environmental impact while supporting light, energy-saving builds.

Elevate Your Production with XINBO Light Steel Keel Machines – Partner for Success

Ready to upgrade your building workflows with top-notch efficiency? As a leading maker, XINBO invites you to check out our premium light steel keel forming machines, built for your high-volume needs.

Contact our expert team today for a free consult, detailed quotes, or virtual demo. Visit www.cnxinbo.net to grab spec sheets, request samples, or plan a site visit. Don’t stick with old methods—invest in XINBO and build the future, one precise keel at a time. Email serena@cnxinbo.net or call +8615003216790 now to start!

Related Posts

-

-

Good Price and Quality IBR Trapezoidal Roof Sheet Roll Forming Machine | IBR Roof Sheet Forming Machine Factory

-

Efficient and Versatile: Light Steel Keel Forming Machine

-

High-Quality Roll Shutter Door Roll Forming Machine: Efficient and Reliable

-

Top 5 Advantages of Using a China Floor Decking Roll Forming Machine in Your Business

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia