Efficient Gutter Production: How to Maximize Your Seamless Gutter Machine Features

Understanding Seamless Gutter Machines

Seamless gutter machines are essential tools in the gutter production industry, allowing for the efficient creation of seamless gutters without any joints or seams. These machines play a crucial role in ensuring that gutters are produced with precision and speed, meeting the demands of both residential and commercial projects.

What is a Seamless Gutter Machine?

The Basics of Gutter Production

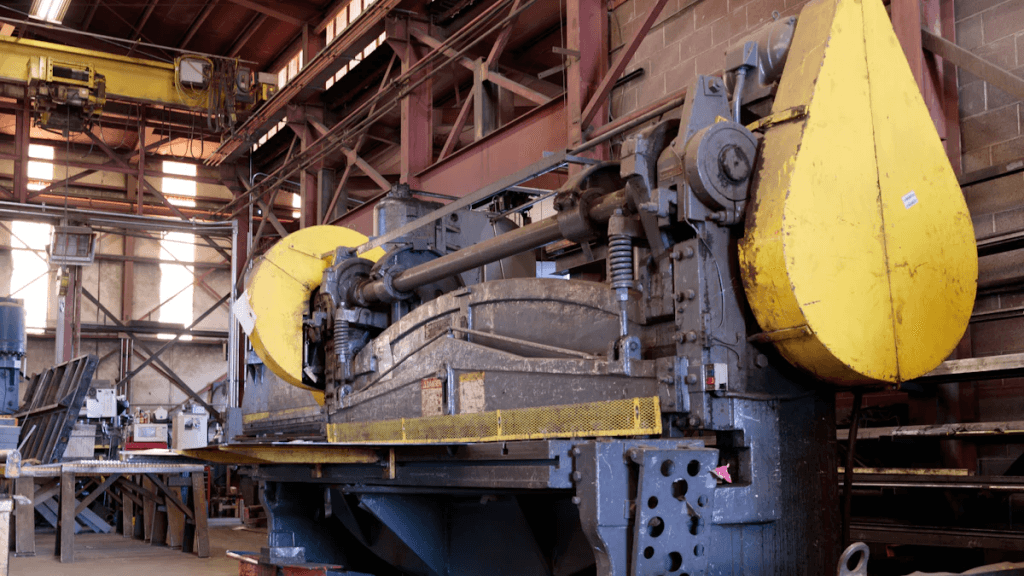

A gutter machine is a specialized equipment designed to fabricate seamless gutters on-site. It consists of various components such as the material reel, forming rollers, and cutting mechanism. The process begins with feeding the coil stock into the machine, where it undergoes shaping and cutting to produce seamless gutters of custom lengths.

Types of Gutter Profiles

Seamless gutter machines are versatile and can produce different gutter profiles to suit varying architectural styles and functional requirements. Common profiles include K-style, half-round, and fascia gutters, each offering distinct aesthetic and functional benefits for different types of properties.

The Importance of Seamless Gutters

Benefits for Homeowners

Seamless gutters offer numerous advantages for homeowners. They eliminate the risk of leaks at seams, reducing maintenance needs and potential water damage to the property’s foundation. Additionally, their sleek appearance enhances the overall curb appeal of the home.

Advantages for Businesses

For businesses involved in gutter installation or manufacturing, seamless gutter machines provide a competitive edge by enabling them to offer high-quality, custom-fit gutters efficiently. This can lead to increased customer satisfaction and loyalty, ultimately contributing to business growth and profitability.

Key Features of Your Gutter Machine

Seamless gutter machines boast several key features that contribute to their efficiency and versatility, making them indispensable tools for gutter production businesses.

Material Compatibility and Versatility

When it comes to gutter machines, one of the most crucial aspects is their material compatibility. These machines are designed to work with various materials, including aluminum, steel, and copper. The ability to accommodate different materials allows for greater flexibility in meeting specific customer requirements and adapting to the unique environmental conditions of different regions.

In addition to material compatibility, seamless gutter machines offer remarkable versatility in producing different gutter profiles. Whether it’s the popular K-style gutters or the classic half-round profiles, these machines can effortlessly fabricate a wide range of gutter styles. This versatility ensures that gutter installation businesses can cater to diverse customer preferences and architectural needs without investing in multiple specialized machines.

Portability and Ease of Use

The portability of a seamless gutter machine is a significant advantage for contractors and installers who frequently work on-site. These machines are designed with mobility in mind, allowing them to be easily transported from one location to another as needed. This portability enables contractors to bring the machine directly to the project site, minimizing logistical challenges and streamlining the installation process.

Seamless gutter machines prioritize ease of use, simplifying the setup process for operators. With intuitive controls and ergonomic design elements, these machines can be set up quickly and efficiently. The user-friendly nature of gutter machines also contributes to safer operation practices, minimizing the risk of errors or accidents during production.

By prioritizing material compatibility, versatility in gutter profile production, portability, and ease of use, seamless gutter machines empower businesses to maximize their production capabilities while delivering high-quality gutters tailored to their customers’ specific needs.

Xinbo Machine Making Co. Ltd is a leading manufacturer of roll forming machines, established in 2014 in China. The company specializes in the production of various types of roll forming machines, which are used in the manufacturing industry to shape metal sheets into specific forms.

The company is committed to providing high-quality products and services. Each machine is inspected three times before shipping to ensure all parts and profiles meet the customers’ requirements. Xinbo also offers custom services, with a team of professional engineers and designers who can design detailed drawings as per customers’ needs in a short time.

Xinbo’s gutter machines are known for their efficiency, precision, and durability. They are easy to operate and require minimal maintenance, making them a cost-effective solution for various industries, including construction and manufacturing.

Maximizing Efficiency: Tips and Tricks

Efficient operation of a gutter machine is essential for maximizing productivity and ensuring the production of high-quality gutters. By optimizing machine settings and implementing routine maintenance practices, gutter production businesses can streamline their operations and minimize downtime.

Optimizing Gutter Machine Settings

Adjusting for Material Thickness

One crucial aspect of optimizing a gutter machine is to adjust the settings according to the material thickness being used. Different materials, such as aluminum, steel, or copper, may require specific adjustments to the forming rollers and cutting mechanisms to ensure precise shaping and cutting. By calibrating the machine based on the material being processed, operators can achieve consistent and accurate gutter production, minimizing material waste and rework.

Speed Settings for Quality Control

Another key factor in maximizing efficiency is to carefully manage the speed settings of the gutter machine. While higher speeds may seem advantageous for increasing production output, it’s essential to find a balance that prioritizes quality control. Adjusting the speed settings based on the material type and profile being fabricated can help maintain optimal product quality while meeting production targets. This approach minimizes errors and ensures that each gutter produced meets the required specifications.

Routine Checks and Maintenance

Preventative Maintenance Tips

Implementing regular preventative maintenance measures is crucial for prolonging the lifespan of a seamless gutter machine. This includes lubricating moving parts, inspecting electrical components, and verifying alignment to prevent premature wear and tear. By adhering to a scheduled maintenance routine, businesses can avoid unexpected breakdowns and costly repairs, thus maintaining uninterrupted production capabilities.

Troubleshooting Common Issues

Despite proactive maintenance efforts, occasional issues may arise during gutter fabrication. It’s important for operators to be familiar with common problems such as misaligned forming rollers or irregular cuts, enabling them to perform basic troubleshooting procedures promptly. Having a checklist for common issues and solutions readily available can minimize downtime by swiftly addressing any operational hiccups that may occur.

Maintaining Your Gutter Machine for Longevity

After investing in a seamless gutter machine, it is crucial to prioritize regular maintenance to ensure its longevity and consistent performance. By adhering to a structured maintenance regimen, gutter production businesses can extend the lifespan of their machines while upholding the quality of gutter production.

The Importance of Regular Maintenance

Extending the Life of Your Machine

Regular maintenance is essential for enhancing the longevity and operational efficiency of your seamless gutter machine. By implementing systematic inspections, ensuring proper lubrication of moving parts, and conducting comprehensive cleaning, companies can effectively reduce wear and tear on essential components. This proactive strategy helps maintain the machine’s optimal functionality over an extended period.

Ensuring Consistent Production Quality

In addition to longevity, regular maintenance plays a pivotal role in ensuring consistent production quality. Well-maintained machines are less prone to operational issues and deviations in gutter fabrication, resulting in a higher standard of finished products. This commitment to quality not only satisfies customer expectations but also enhances the reputation and reliability of the business within the industry.

Professional Servicing and Parts Replacement

When to Seek Professional Help

While internal maintenance measures are essential, there are instances where seeking professional servicing becomes necessary. Gutter production businesses should consider engaging professional technicians for comprehensive inspections and servicing at regular intervals. Professional help is particularly vital for intricate tasks such as recalibrating forming rollers or addressing electrical system malfunctions.

Finding Quality Replacement Parts

In the event of component wear or malfunction, sourcing quality replacement parts is paramount to maintaining the seamless gutter machine’s optimal performance. Businesses should establish partnerships with reputable suppliers who offer genuine replacement parts specifically designed for their machine model. Utilizing authentic parts ensures compatibility and reliability, safeguarding against potential operational disruptions.

Implementing a well-structured maintenance plan that encompasses both internal upkeep and professional servicing is instrumental in maximizing the operational lifespan and performance consistency of seamless gutter machines. By prioritizing regular maintenance practices, gutter production businesses can uphold efficiency and product quality while safeguarding their long-term investment in gutter fabrication equipment.

Conclusion

Final Thoughts on Maximizing Efficiency

In conclusion, maximizing efficiency in seamless gutter production goes beyond the capabilities of the machine itself; it encompasses a holistic approach that integrates technological prowess with meticulous care and attention. By leveraging the versatility and portability of these machines while adhering to best practices in maintenance and operation, businesses can elevate their productivity while delivering superior gutter solutions to their customers.

It is imperative for gutter production businesses to recognize that investing in a seamless gutter machine is not just about acquiring a piece of equipment; it’s about embracing a commitment to excellence in every aspect of gutter fabrication. Through continuous optimization and unwavering dedication to quality, businesses can set new standards in seamless gutter production, solidifying their position as industry leaders.

As technology advances and market demands evolve, staying at the forefront of efficient gutter production requires a dynamic approach that combines innovation with reliability. Seamless gutter machines serve as catalysts for this evolution, empowering businesses to meet diverse customer needs with precision and speed.

In essence, by harnessing the full potential of seamless gutter machines through strategic utilization and meticulous upkeep, businesses can pave the way for unparalleled efficiency in gutter production, setting new benchmarks for quality and customer satisfaction within the industry.

Related Posts

Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→

Spanish

Spanish Russia

Russia