How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

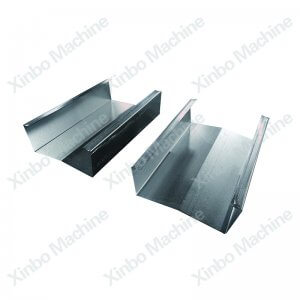

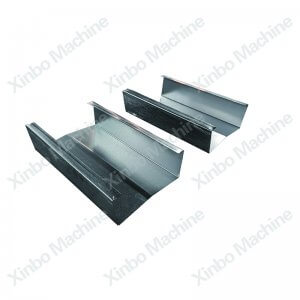

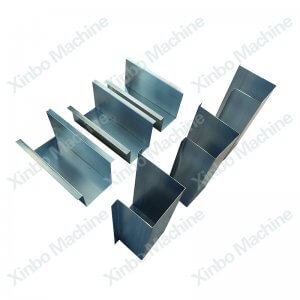

Factory Supply Portable Metal Downspout Gutter Elbow Rain Roll Forming Machine Seamless Bending Making Machine Gutter Machine

This gutter roll forming machine is for steel or aluminum sheet cold form industries. It can form rain gutter profiles according to customer’s requirement continuously, automatically cut to length. The equipment adopts PLC control, AC frequency and adjusting the speed technology, and it realizes the continuous automatically production. Therefore, it is really a new type of energy-saving and high-effective equipment for metal rain gutters. And it has many advantages, just like high forming speed, low noise, stable transmission, easy operation, good appearance and so on.

|

No. |

Item |

Specification |

|

1. |

Processing Material |

Aluminuim,Galvanized |

|

3. |

Processing Thickness(mm) |

0.3-0.7 |

|

4. |

Material of Rollers |

45# steel,with hard chrome coated |

|

5. |

Production Speed |

0-14 m/min |

|

6. |

Roller Driven |

Decelerating Motor+Chain Transmission |

|

7. |

Cutting Model |

Hydraulic Cutting |

|

8. |

Length Measurement |

Encoder |

|

9. |

Control Style |

PLC |

|

10. |

Station of roller |

As engineer designing |

|

11. |

Total Power |

3+3+3+0.75kw |

|

12. |

Voltage |

380V 50HZ or at buyer’s request |