How Can We Help ?

If you need any helps,please feel free to contact us.

If you need any helps,please feel free to contact us.

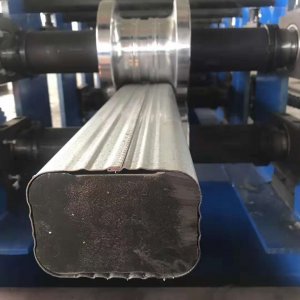

Downpipe roll forming machine

The downpipe machine and elbow machine use color steel plates as raw materials to make closed color steel downpipes after cold bending and automatic locking, and make downpipe elbows with different matching angles after bending. The downpipe machine is composed of uncoiling system, feeding guide system, roll forming system, shearing system, finished product support, hydraulic system and automatic control system. The matching elbow forming machine is suitable for bending and shrinking of the corresponding color steel downpipe. It is produced automatically by mechanical control, and the bending angle can be adjusted manually. The products produced by this equipment are widely used in steel structure buildings, villas and other sewer.

|

No. |

Item |

Specification |

|

1. |

Processing Material |

Aluminuim,Galvanized |

|

3. |

Processing Thickness(mm) |

0.3-0.7 |

|

4. |

Material of Rollers |

45# steel,with hard chrome coated |

|

5. |

Production Speed |

0-14 m/min |

|

6. |

Roller Driven |

Decelerating Motor+Chain Transmission |

|

7. |

Cutting Model |

Hydraulic Cutting |

|

8. |

Length Measurement |

Encoder |

|

9. |

Control Style |

PLC |

|

10. |

Station of roller |

As engineer designing |

|

11. |

Total Power |

3+3+3+0.75kw |

|

12. |

Voltage |

380V 50HZ or at buyer’s request |