Good quality

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

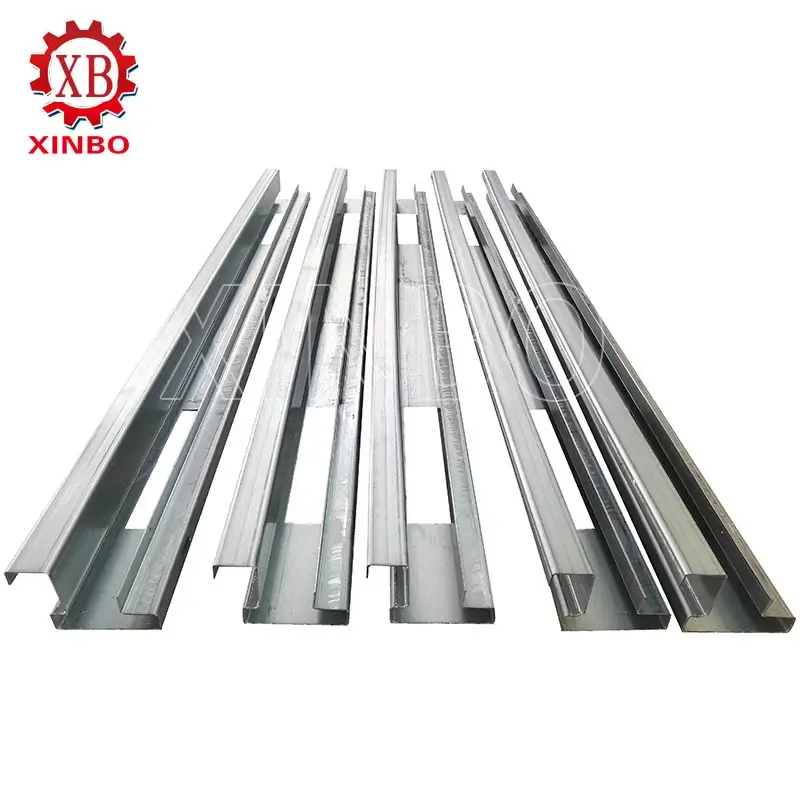

VIEW MORE→Container houses are a popular choice for portable, budget-friendly, and eco-kind buildings. They’re made from pre-built steel sections and sandwich panels, put together on-site to create flexible spaces for living, working, or storage. A key part is the top beam, which gives strong support and keeps the structure steady. The Container House Top Beam Roll Forming Machine is a special tool designed to make these top beams with exactness and speed. This guide covers the machine’s definition, how it works, its features, parts, uses, and benefits, giving new users a clear picture of its role in building container houses. The details come from trusted sources, ensuring accuracy for those eager to learn about this technology.

A Container House Top Beam Roll Forming Machine is a type of roll forming machine built to create top beams for container house construction. Roll forming is a nonstop process where a flat metal strip, usually galvanized or cold-rolled steel, moves through rollers that bend it bit by bit into a specific shape. For container houses, the machine turns the metal strip into a channel or beam that acts as the top structural piece. This beam links with corner posts and wall panels to keep the structure solid. These machines are vital for making parts for pre-built container houses, which are assembled on-site to cut down on environmental impact and building time.

The Container House Top Beam Roll Forming Machine works using roll forming, a bending process that shapes a flat metal strip into an exact beam shape. It has these main steps:

A coil of metal, often galvanized or cold-rolled steel 1.2 to 3.0 mm thick, sits on a hydraulic decoiler. The decoiler unwinds the coil, feeding a steady stream of material into the machine.

The metal strip passes through a leveling tool with rollers, like three on top and four below. This flattens out any bends or twists from storage or transport, making the strip smooth and even before shaping.

The main part is the roll forming section, with 18 to 20 stations of carefully designed rollers. Each station bends the strip a little more, slowly forming the top beam shape. Rollers, made from strong materials like Gcr15 bearing steel or SKD11, are built to reduce stress on the metal while getting the right form.

Once the beam is shaped, a hydraulic cutting tool trims it to the needed length. The cutter, often using Cr12MoV steel dies, makes clean, precise cuts to keep the beam’s size exact.

A programmable logic controller (PLC) runs the whole process, syncing the decoiler, roll forming, and cutting. The PLC lets operators set details like beam length and amount, ensuring steady output with little hands-on work.

This process is quick, running at speeds up to 20 meters per minute, and makes uniform beams with little waste. The gradual bending keeps the metal strong, perfect for the tough needs of container house building.

Container House Top Beam Roll Forming Machines have handy features that boost their work and make them great for high-quality top beams:

High Precision: They make beams with exact sizes, so parts fit perfectly during container house assembly. Advanced controls and well-made rollers help with this accuracy.

High Production Speed: They run at speeds from 5 to 500 feet per minute (1.5 to 152.4 m/min), depending on the job, ideal for big batches.

Automation: PLC systems automate shaping, cutting, and punching, cutting labor costs and mistakes.

Adjustability: Rollers and spacers can be tweaked by hand or auto to make beams of different sizes and shapes, flexible for various container house designs.

Durability: Made with tough materials, like high-grade steel shafts and hardened steel rollers, they handle constant work.

Energy Efficiency: Built to use less power, they keep high output while keeping costs low.

Material Versatility: They process galvanized steel, cold-rolled steel, stainless steel, and aluminum, with strength up to 345 MPa.

These features make the machine a trusty, efficient tool for container house makers.

A Container House Top Beam Roll Forming Machine has these key parts, each playing a role in production:

| Component | Description |

|---|---|

| Hydraulic Decoiler | Holds and unwinds the metal strip, usually up to 5 tons, for a smooth feed. |

| Feeding and Guiding Device | Lines up and directs the strip into the roll forming section, keeping it straight. |

| Leveling Device | Flattens the strip with rollers to make it uniform before shaping. |

| Roll Forming Section | Has 18–20 stations with rollers (e.g., Gcr15 or SKD11) that shape the strip into the beam. |

| Hydraulic Cutting Device | Cuts the beam to the right length with Cr12MoV steel dies for precision. |

| Run-Out Table | Supports cut beams as they leave, making collection easy. |

| Hydraulic Station | Gives hydraulic power (e.g., 11 kW) for cutting, punching, and more. |

| PLC Control System | Runs the process, controlling details like length and amount. |

| Punching Tool (Optional) | Adds holes or features for assembly. |

| Crimping Device (Optional) | Locks or secures beams, especially for box beam setups. |

These parts work together for a smooth, efficient process from raw metal to finished top beam.

The main use of the Container House Top Beam Roll Forming Machine is making top beams for pre-built container houses. These houses serve many purposes, including:

Temporary Housing: Homes for workers, disaster relief, or residents in remote spots.

Portable Offices: Workspaces for construction sites, far-off places, or short-term businesses.

Storage Units: Warehouses, shipping containers, or storage for goods and gear.

Retail Spaces: Pop-up shops, showrooms, or temporary retail spots.

Educational Facilities: Classrooms or training centers in areas without permanent buildings.

Medical Clinics: Field hospitals or temporary medical setups for emergencies.

Top beams are vital for holding up the roof and linking with corner posts and wall panels, keeping container houses strong. These beams can also work in other projects needing similar channels, like light steel framing for buildings or modular structures.

The Container House Top Beam Roll Forming Machine has these benefits over traditional methods:

Cost-Effectiveness: Roll forming cuts waste and labor costs, great for big production.

High Production Speed: The nonstop process makes beams fast, meeting mass production needs.

Uniformity: Beams have consistent sizes and quality, ensuring reliable assembly.

Material Efficiency: Uses metal strips well, reducing scraps and costs.

Versatility: Adjustable rollers make various beam sizes and shapes for different designs.

Low Maintenance: Built tough, these machines need little upkeep, cutting downtime.

Environmental Benefits: Efficient material and energy use supports eco-friendly container house building.

These perks make the machine a must-have for makers wanting to build top beams efficiently.

This table shows typical specs for a Container House Top Beam Roll Forming Machine, based on industry standards:

| Parameter | Specification |

|---|---|

| Raw Material | Q235 Galvanized steel, cold-rolled steel, stainless steel, aluminum |

| Material Thickness | 1.2–3.0 mm |

| Yield Strength | ≤345 MPa |

| Coil Weight | Up to 5 tons |

| Coil Inner Diameter | 480–520 mm |

| Coil Outer Diameter | Up to 1250 mm |

| Forming Stations | 18–20 stations |

| Rolling Speed | 0–20 m/min (excluding punching and cutting) |

| Motor Power | 15–35 kW |

| Hydraulic Power | 11 kW |

| Roller Material | Gcr15 bearing steel, SKD11, or D2 with quenching treatment |

| Shaft Material | High-grade 45# steel, diameter 80 mm |

| Cutting Mechanism | Hydraulic cutter with Cr12MoV steel dies |

| Control System | PLC with inverter, transformer, and encoder |

Specs may vary based on machine design and job needs.

Looking to enhance your production efficiency with a Container House Top Beam Roll Forming Machine? XinBo machine is a 100% manufacturer established in China since 2014. Quality assurance is provided by a team of our machine professional designer and producers and workers. Contact Xinbo Machine today for a custom solution tailored to your specific needs. With over 9 years of experience and cutting-edge technology, we provide high-quality machinery designed for optimal performance. Our team is ready to help you with personalized consultations and quick delivery times.

Get in touch now:

📞 Tel: +8618931871722

📧 Email: serena@cnxinbo.net

💬 Whatsapp: +8618931871722

Transform your manufacturing process with Xinbo’s reliable, cost-effective roll forming solutions. We look forward to working with you!

XinBo machine making CO. LTD is a professional manufacturer and exporter in roll forming machine,

VIEW MORE→